We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

When I teach a woodworking class, I give my students free reign with my tools. It’s a great way for them to get a feel for tools that are sharp and in order. It’s also a great way to get a broken turning saw.

During the last few years, students have destroyed my turning saws at least three times by over-tensioning them. Even though I tell them: Do not touch the tensioning or you will have to touch my no-no square (a private joke).

So they crack the cheeks of my turning saws all the time, put the splintered mess on my bench and say something like: Good thing it’s wood so you can make another.

Today I started making a few turning saws and a bunch of replacement parts for some upcoming classes. I’m teaching a class on making these saws in Germany next month, and I really need a working turning saw. My band saw has been getting too much of the twisty sawing jobs lately.

So how do you build a turning saw without a turning saw? With your band saw.

My design uses the hardware from Tools for Working Wood and a design from the fan-blankety-tastic book “Antique Woodworking Tools” by David R. Russell. I’m using some really old mahogany from Midwest Woodworking.

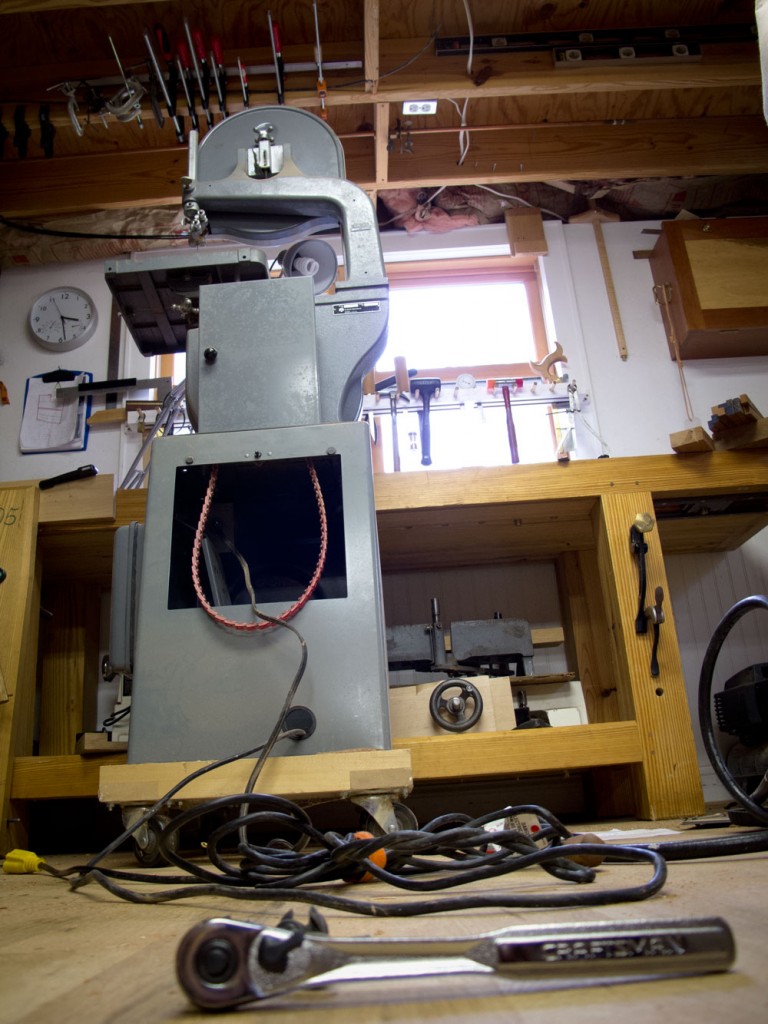

As I was cutting some of the curves on the cheeks with my 40-year-old Delta 14” band saw, the motor spun to a stop. I checked the cord. No joy. After taking the whole thing apart, I found the motor’s thermal overload switch to be the culprit. It’s a 1/2 hp Craftsman AC motor from one of my grandfather’s machines and was made in 1940. I guess 73 years isn’t a bad run for an AC motor.

On my way to take the motor to the repair shop, I told Megan Fitzpatrick about it – my dang band saw crapped out while I was using it to make a turning saw to take work away from the band saw.

“Resistentialism” is all she replied.

Grrr. The woman has a mouth like a redheaded librarian pirate.

Look the word up if you must, but she’s right.

The good news is that my 73-year-old motor just needs some new parts and will be back in business next week. Its windings are in great shape.

— Christopher Schwarz

If you want to master your band saw, read the book that I read: “The New Complete Guide to the Band Saw” by Mark Duginske. It is all you really need.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Chris- Can you point me in the right direction to learn how to diagnose and do these repairs? I have an old delta drill press with the same malady, about the same age. I don’t know how to tell if its windings, switch, or cussedness. Sorry- Can’t abide by the Resistentialism doctrine since I can’t figure out how to pronounce it. Now, Frisbeetarianism, that I can say.

That term pretty much sums up half the equipment in my shop ! lol

What is a turning saw?

In the laboratory, pH meters are the resistentialists!

Oh DO look up the word! Wikipedia has a great page devoted to it.

xMike

Chris,

Is your plan available, or do I have to go to Germany to learn it?

Ralph Boomer

Chris, I have that same bandsaw and it’s not nearly 40 years old. I think you were exaggerating it’s age ! Besides your not even that old !

“Les choses sont contre nous.”

They are against us.

I hardly needed the validation for this pronounced aspect of my daily life, but… it’s good to have. Same goes for MCS.

“Resistentialism”……..now that’s where an English major comes in handy. Great word, thanks.

So a turning saw is essentially a bow saw pretending to be a fret saw?

I am also making my first turning saw right now. Without a bandsaw in my shop I just hack away the wood with saws, chisels and a rasp. Makes for quick work too. I always understood from the tfww website that easilly loosing the setting is a feature of the saw. So you can make adjustments quickly, almost on the fly, without having to untension the saw first. While sawing you keep the saw from turning around the pin with your index finger. Well, I’m going to try the theory next week or so when the handles are ready.

Brandon,

I have hardware from both TFWW and Bill. I’m making bowsaws using both and will report back.

I’m currently making my first turning saw. I loved the one that was done on the woodwrights shop a year or two ago, and it turns out pop wood did an article on that very saw. I bought that article online and am working from those plans. I’m very happy. I really like Bill Andersons tapered pins, so I ordered those from his website.

Do you have any thoughts on tapered pins vs the ones from TFWW? It seems the tapered pins might keep their setting better than the straight pins.