We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

In my book, Jeff Miller might just be one of the keys to the future of woodworking.

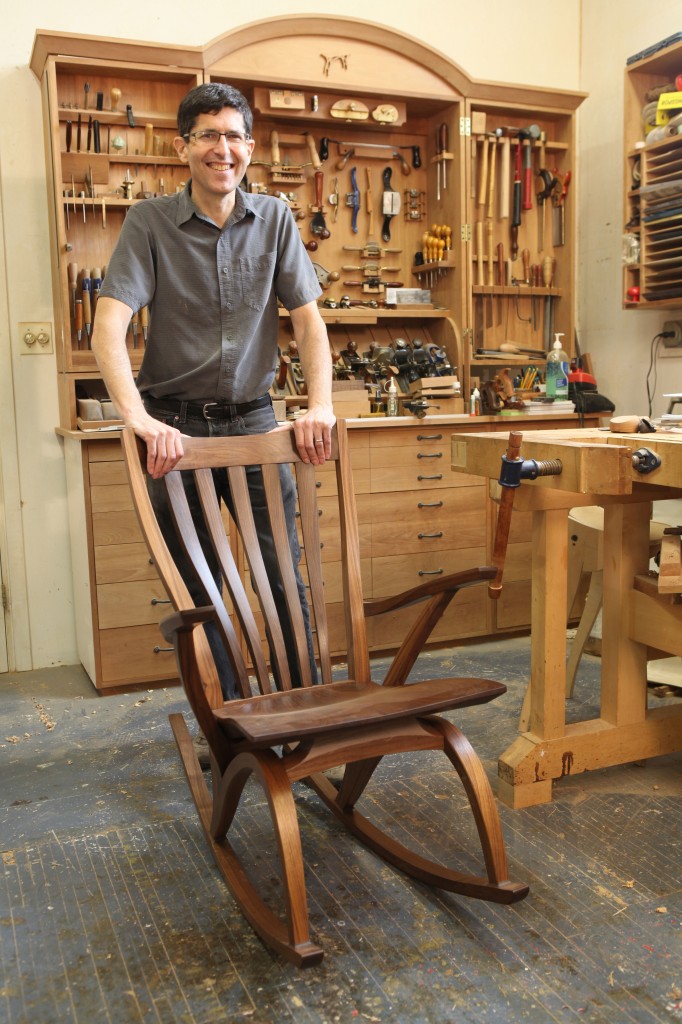

The furniture he’s built during the last three decades is decidedly contemporary. It has clean lines, simple curves and impeccable joinery and wood selection. Yet Miller manages to fold a surprising number of traditional tools into his tool kit – stuff that you normally see sitting on a half-finished Chippendale highboy.

He has a half set of hollow and round planes. Router planes. Lots of spokeshaves and a full arsenal of planes. Yet his furniture looks like the sculpted stuff turned out by the angle-grinder-and-belt-sander enthusiasts.

This week I got to spend an afternoon with Miller to interview him for an upcoming article in Popular Woodworking Magazine, plus I got a peek at the table he’s building for an upcoming issue of of the magazine. It’s one of Miller’s signature pieces – heck, the design is even his shop logo.

With the table’s parts arrayed around his shop in varying stages of completion, Miller discussed the project and how it was an interesting combination of challenges and surprisingly easy operations. I shot the following short video of the interview.

Look for an article on the table and Miller in upcoming issues of the magazine. And if you are interested in chairmaking or contemporary design, then you should definitely check out Miller’s blog: http://furnituremaking.com/wordpress/

He’s also the author of several great woodworking books that I have on my shelf:

• “Beds” (Taunton) is one of the bestselling books on the topic. A great book with a variety of designs and construction options.

• “Chairmaking and Design” (Linden) is the only good book I’ve ever found on constructing modern frame-style chairs.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I too have a very similar point of view about Jeff. I worked as a part time apprentice with Jeff for about 7 years. He taught me so much during that time, including how he builds this table. Seeing the table makes you want to touch it. It’s strength is pretty amazing as well. You can take the large curve, place it on end, and hang your entire body weight on it, producing very little flex.

The top has a nice inlay detail on it as well. Looking at this table, you’ll see how it influenced subsequent design elements in his chairs, rockers, etc. It’s details and joinery details only scratch the surface of what he does with bent laminations.

Personally, I need to take the plunge and build one myself. My only regret is that I don’t live in Chicago anymore. I’d like to borrow the bending jigs and his clamps.

Looking forward to the article. His writing is always interesting and informative.

– Andy Brownell

Ok, was I the only one that noticed the fantastic stool at around 0:59? Does anyone know where I can find more info on it, some more pics maybe? That thing looks great!

Going to Jeff’s shop for the Lie-Nielsen hand tool event was a surprise, in that it isn’t a really large shop, but he sure gets some beautiful work done in there. And, he is definitely a class act kind of guy.

I totally agree with your comments regarding Jeff Miller’s direction with his studio furniture. His combination of old school craftmanship and clean, contemporary design are a combination that avoids the mass of replica furniture that flows from so many workers of wood today.

In addition to being an extraordinarily skilled person he is a patient and gifted teacher of his craft. I look forward to reading his article in the future issue.