We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Campaign chests had to take a beating. They traveled all over the British Empire during the 18th, 19th and early 20th centuries. And yet they bore their burden without complaint or explanation.

Which is to say: When you look at most campaign chests, it’s unclear how they were constructed. Yes, the drawers were dovetailed. But the carcases – at first glance – don’t really tell you much. And some of the examples are liars – there are nails driven through the tops and sides of these beauties.

After you examine a couple hundred of these chests, patterns begin to emerge and their construction becomes evident.

I grew up with campaign chests owned by my grandparents where the carcases were assembled with half-blind, sometimes called half-lap, dovetails. The tails were on the horizontal bits and the pin sockets were on the vertical parts. You’ll also find examples with the reverse arrangement – tails on the sides and pins on the tops and bottom.

Either arrangement of this visible dovetail joint exists, but it is somewhat uncommon in campaign furniture in my experience.

Here’s what I’ve found: Most campaign chests have two sections, a lower and an upper. The lower case is joined entirely by half-blind dovetails in a way that the joinery is not evident when the two sections are stacked together. Lift off the top section, however, and you can see the joints.

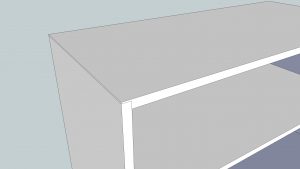

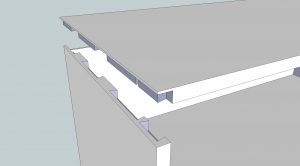

The top case has two kinds of joints. Its bottom is joined to the sides using the same arrangement as in the lower case. When the two cases are stacked, you cannot see any joinery.

The top, however, is joined to the sides with full-blind dovetails. This rabbeted dovetail form gives immense strength, is easy to cut (really!) and the joint doesn’t show. As I’ve been designing and cutting the joints for my own version of a campaign secretary, I’ve marveled at how these hidden joints are much easier to make than through-dovetails.

Why are they easier to make? You can make your pins and tails wider. And the fit doesn’t have to be airtight – just glue-tight.

For details on this joint, see Glen Huey’s article on the desk in the November 2011 issue of Popular Woodworking Magazine – that explains it. You can download the issue through ShopWoodworking.com.

Before you scoff at this joint, let me tell you a little secret: Most people say that through-dovetails are easier than half-blind or full-blind dovetails. I think they are wrong. Through-dovetails have lots more surfaces that show – both at the baselines and along the joint’s cheeks.

The more surfaces you hide, the less persnickety you have to be to achieve dovetail awesomeness. I like cutting half-blinds and full-blinds more than through-dovetails. Promise. But that’s just me.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Question, how do you layout either the pins or the tails for a double blind dovetail without a jig?

Please post the hardware info. I have searched for twenty years for the right stuff and while the handles are available (mostly from London), the braces and corners available from even the best hardware outlets are CHEAP imitations that can be seen from across the room. I saw an earlier e-mail from someone willing to drop off a copy of “British Campaign Furniture – Elegance Under Canvas”. You live in different circles from me. At over $200.00 a copy, that’s a nice drop off! While the book is annotated, you will go crazy trying to track down sources for the brass corners, hinges, rod, and the catches and lifts to lock cabinets and wardrobes together. I’m looking forward to that information.

It appears from the Sketchup pics that the pins are on the sides of the case and the tail on the top and bottom. It would seem that if the joint were to fail it would be the bottom blowing out when the case was picked up by the side handles. Wouldn’t it be stronger with the tails on the sides? Or is my failure mode wrong?

Seems like a good future class. Also just found some 24″ – 36″ wide African Mahogony

Using modern glues that produce a joint that is stronger than the surrounding wood (in long grain joints), the strength of the joint is primarily a function of the total long grain glue surfaces. It would seem that the strongest joints would maximize this total surface.

A 1/2 blind joint uses the full thickness of the tail board and about 2/3 of the pin board. A full blind joint uses only 2/3 of each board. This would result in a weaker joint given that the same number of pins and tails are used.

The other consideration is the number of surfaces. I try to use pin and tail spacing about the same as the thickness of the boards when they will be hidden.

If full-blind dovetails are stronger and easier to cut than half-blinds, then why weren’t all of the joints done with full-bllinds? I saw Ernie Conover make some at NWA/Saratoga Springs in March 2011 but still couldn’t fully appreciate what he was trying to convey. Sorry, but I’m slow and thick.

Is there an interesting story behind how your grandparents came to own campaign chests?

Frankly, these sorts of projects are a great opportunity for chickens like me to start using dovetails.

Most Asian furniture is joined in such a way as to hide and bury end grain, leading to more use of full-blind dovetails than in western furniture styles. There are a few different reasons for this. Some had to do with the prevailing aesthetic and style choices in Asia. But one practical reason is that wood movement from moisture is minimized if end grain is hidden, and many areas of Asia experience quite large humidity swings throughout the year, and their houses were often much more exposed to the outside air compared to the western world. For a campaign chest, which would also be exposed to a wide variety of environments, this would be a benefit as well.

I understand the part about “what doesn’t show doesn’t have to be perfect”, but what is the rationale for wider pins/tails when they are blind? Aesthetically I understand that, but don’t you give up strength?

Great Post. I wondered why these chests would be all dovetail and a rabbit join on the top. I’ll have to try a double blind myself before I believe you on how easy they are.