We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

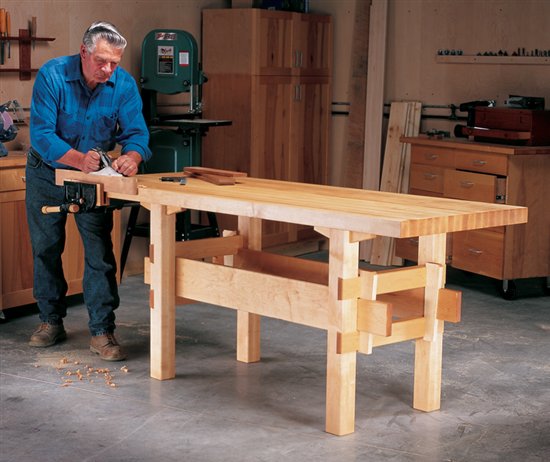

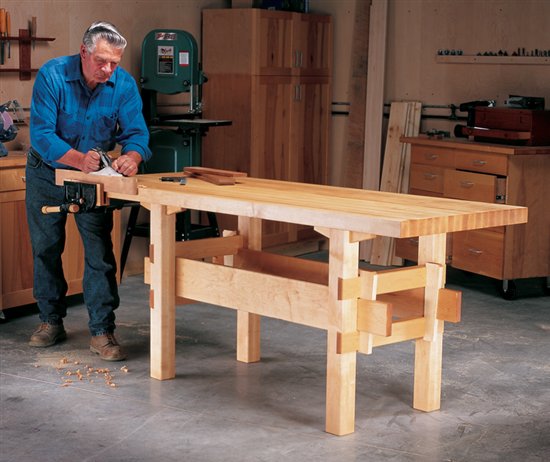

Wedged-Base Workbench

Tablesaw joinery locks it together.

By Tim Johnson

|

This workbench has a top ready for hard use. But it’s the base that

catches your eye. The interlocking joinery, with its dovetails and

wedges, is rock solid, yet it knocks down quickly for moving.

Although it looks complicated, the base is surprisingly easy to build. It’s made from multiples of only five parts that fit

together like the pieces of a puzzle. The

fancy joinery that locks the pieces in

place is nothing more than strategically

located rabbets and dadoes, and they’re

all made on the tablesaw.

|

|

You may also like…

Dream Workbench

Adjustable Workbench

Master Cabinetmaker's Bench

|

|

Cut slots centered in the top of each leg for the brackets

that hold the top (Step A).To keep the leg steady, attach a tall

auxiliary fence to your saw’s rip fence and clamp the leg to a

good-sized rectangular block. Use a featherboard and make the

cut in several shallow passes until you reach the maximum

depth your dado set allows (21⁄8-in., in this case).

|

|

|

|

Cut dadoes on both sides of each top bracket so they

can slip into the dadoes in the leg tops (Step B). Stop blocks at

each end of the miter fence control the width of the cut.

|

|

|

|

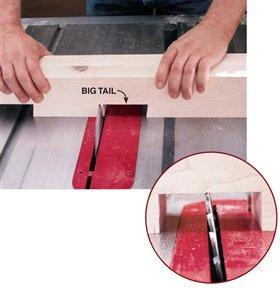

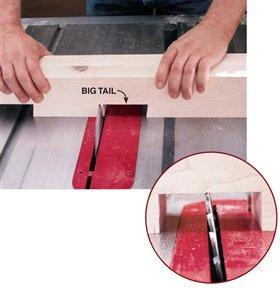

Bevel the edges of each end rail at a 9-degree angle

(Step E).These cuts turn the tongues into big dovetail pins.

Leave a 1⁄4-in. wide flat on the back edge of the rail to ride

against the fence.

|

|

|

|

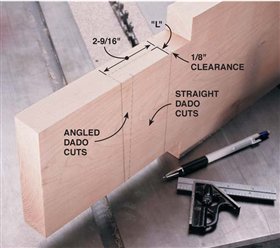

Make angled cuts at the

reference points, turning the leg

dadoes into tails (Step F).Then nibble

away the remaining waste. After cutting

the angle on one side of each dado, flip

the leg over and stand the end rail on the

leg. Align the pin with the unfinished tail, and

mark the leg for the remaining angled cut.

(Inset) Set the height of the blade for cutting the

dovetail corners by raising it so that its teeth barely nick the

top of the dado.

|

|

|

|

Pare the waste from the angled saw cuts with a sharp,

wide chisel to finish the corner.

|

|

|

|

Cut a dado (Step G) in each end rail, starting from the

shoulder of the half-lap. Make it wide enough to house the

side rail.

|

|

|

|

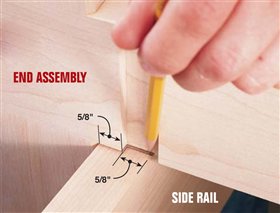

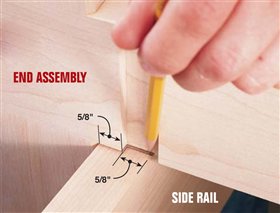

Mark the location of the angled dado in the side rail

that will hold the wedge. Slide the side rail into position and

use the end assembly dado for reference.

|

|

|

|

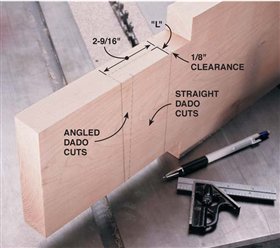

Lay out the side rail wedge dado from the L-shaped mark

you’ve just made (Photo 7). Its leg gives you the depth and its

stem marks the back of the wedge. Extend the dado a bit behind

this line for clearance. Draw the angled front using one of your

wedges held tight against a try square.You can remove most of

the waste from this dado with straight, 90-degree cuts (Step L).

|

|

|

|

Make the final angled cuts in the side rail (Step M). Use

one of the wedges clamped between the rail and the miter

gauge to guarantee that the angle of the dado and the wedge

match perfectly.

|

|

|

|

Slide the wedge home (Step N). Once it has engaged

the dado in the lower end rail, tap it securely into place.

|

|

|

Sources

Woodcraft Supply, woodcraft.com, 800-225-1153, workbench tops.

Your local home center or lumberyard, kitchen countertops.

The story originally appeared in American Woodworker October 1999, Issue #75.

|

|

Purchase the complete version of this woodworking project story from AWBookstore.com.

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.