Everyone I know has a drawer stuffed

with photos that are waiting to be framed.

What often keeps us from getting those

treasures up on the wall is the high cost

of professional framing.

If you’ve ever tried making picture

frames, I’ll bet you got frustrated cutting

the miters and clamping the corners.

We’ve got the perfect solution.

We’ve designed a great looking two-part

frame that’s downright cheap and easy to

make. The pieces are small, so you can use

up some of that scrap wood you’ve been

unable to part with. Plus, with our surefire

mitering and clamping jigs, you can make

frames by the dozen.

The frame and jigs shown here are set

up for 8 x 10 or smaller photos. By using

different mats, you can use one frame size

for different-size photos. You can also

make the frame and jigs larger or smaller

to custom-fit almost any size picture.

Tools and materials

To make the frames you will need a

tablesaw, a router and router table, plus a

dado blade and router bits. To build the

jigs you will also need a hand drill, jigsaw,

hacksaw and a few spring clamps.

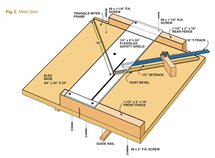

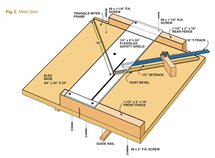

Making and using a miter sled

This tablesaw sled makes perfect miters every

time. You’ll be able to quickly cut accurate multiple

frame parts. Start by cutting all the parts

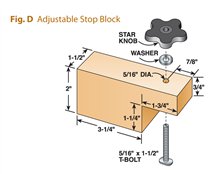

for the sled (Fig. D). You’ll have to

size the guide rails to fit your tablesaw because

slot sizes vary between saw brands. Make the

guide rails so they slide freely, yet have minimal

side-to-side movement. Make them about 1/16″

thinner than the depth of the slots in your

tablesaw. Also make a pair of 1/8″-thick spacer

strips to use when gluing the guide rails to the sled board (Photo 4).

After attaching the guide rails, add the front and rear fences.

Put the sled on your tablesaw with the blade raised about 1″

Now slide the saw sled into the blade until the plywood is cut

to about half of its width.

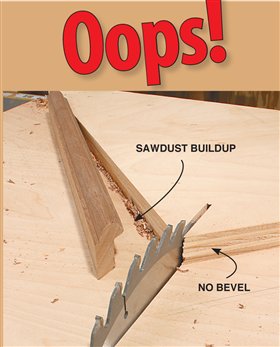

Next, make the plywood triangle. Start with a

16″-square piece of plywood and cut it diagonally with a jigsaw.

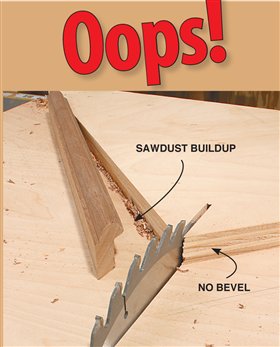

Don’t forget to rout the dust bevel on the bottom side of

the triangle. This bevel helps prevent sawdust from building

up against the triangle and causing miter-fitting problems (see

Oops!, below).

Center the triangle on the saw kerf and attach it to the sled

base with screws (Photo 5). Complete the saw sled with the

addition of the T-track, adjustable stop block and the safety

shield (Photo 6).

Cutting frame parts with this miter sled is a simple two-step

process (Photos 7 and 8).

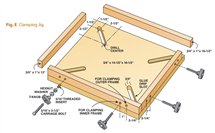

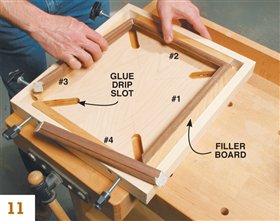

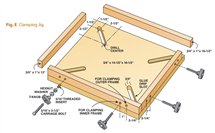

Making and using the clamping jig

This clamping jig takes the pain out of gluing and clamping

miters. Unlike the old one-corner-at-a-time clamps, ours takes

care of all four corners at once!

The clamping jig shown here is made specifically to fit our

frame sizes. You can clamp other size frames by making the

clamping jig larger or smaller.

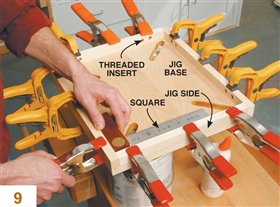

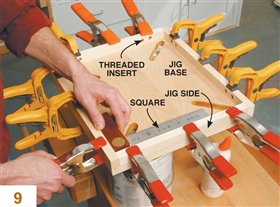

To make the jig, cut the parts according to Fig. E. Drill

3/4″ holes, then cut out the glue drip slots with a jigsaw. Next,

drill for the threaded inserts (see Sources, below) and screw

them in place. Now glue the sides to the base. To ensure

perfectly square frames, the jig sides that don’t have threaded

inserts must be perfectly square to each other (Photo 9).

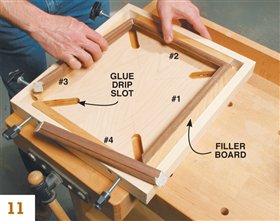

To complete your clamping jig, make the filler boards (Fig.

F). These boards keep the frame centered in the jig, help distribute

the clamping pressure evenly and protect the frame from

the ends of the clamping bolts.

Follow the steps in Photos 10 through 12 to clamp up your

frames. It may take you a couple of frames to get the hang of

clamping all four corners at the same time, but once you do

you’ll be amazed at how fast you can make perfect frames. After

the glue dries, sand the frames. The inner and outer frames

can be glued together before finishing or brad-nailed together

after finishing. If clamping one frame at a time seems too slow

for you, make several clamping jigs and you’ll really be in the

production business.

Oops!

Sawdust buildup can keep your frame material from

laying tightly against the triangle fence. This causes

miter-alignment problems later on. We learned this

the hard way when we built our prototype miter sled

(photo, above). That’s why it’s important to bevel the

bottom of the triangle fence to give the sawdust a

place to go.

Sources

(Note: Product availability and costs are subject to change since original publication date.)

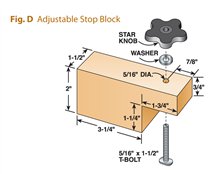

Rockler, rockler.com, 800-279-4441, 2′ Universal T-track, #22104;

5/16″ x 18 x 1-1/2″ T-slot bolt, #83311;

5-star jig knob, #23812;

2″ T-knob, #71514;

5/16″ x18 threaded inserts, #28811.

Rust-Oleum, rustoleum.com, 877-385-8155, American Accents, available at

hardware, paint and discount stores nationwide.

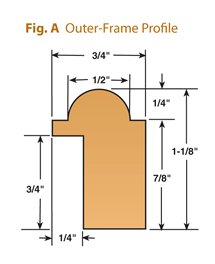

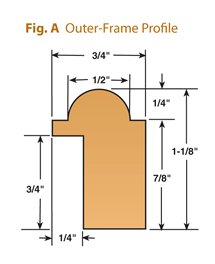

Fig. A: Outer-Frame Profile

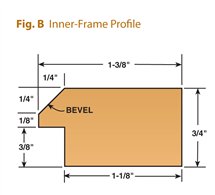

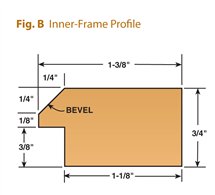

Fig. B: Inner-Frame Profile

Fig. C: Miter Sled

Fig. D: Adjustable Stop Block

Fig. E: Clamping Jig

Fig. F: Clamping Jig Filler Boards

This story originally appeared in American Woodworker October 2002, issue #122.

October 2002, issue #96

Purchase this back issue. |

|

Click any image to view a larger version.

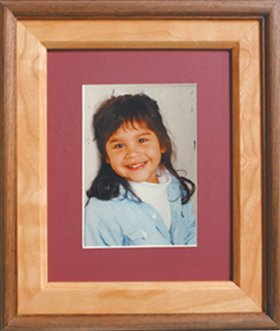

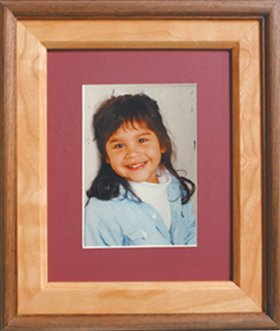

Two small photos mounted with

a twin mat in a walnut frame.

4 x 6 photo mounted with a double

mat in a mahogany and walnut frame.

5 x 7 photo mounted with a vertical

mat in a maple and walnut frame.

8 x 10 photo mounted without a

mat in a cherry and walnut frame.

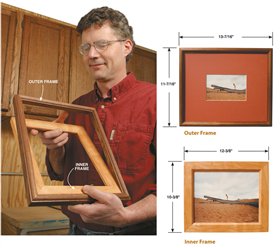

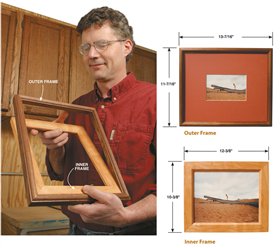

Our frame design has two parts, which can be made of different woods or

even used as two separate frames!

1. Rout the frame profiles on your router table. Keep things safe by using

featherboards and push sticks.

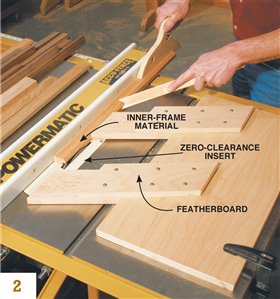

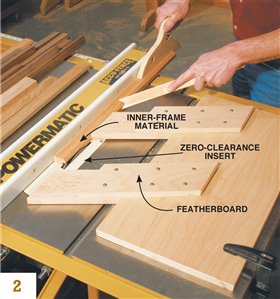

2. Cut the rabbet in the inner-frame material with a dado blade.

Use a zero-clearance insert to fully support the frame material

and featherboards to keep the material against the fence while

making the rabbet.

Caution: Blade guard must be removed

for this cut.

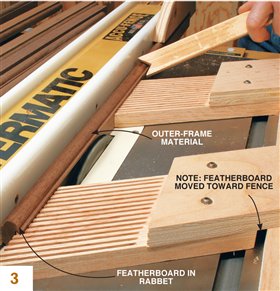

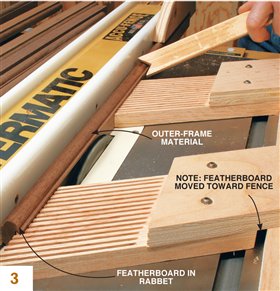

3. Cut the rabbet in the outer-frame material. Adjust the outfeed

featherboard so it rides inside the rabbet.

Caution: Blade guard must be removed

for this cut.

4. Make a miter sled for cutting the frame pieces. Begin by gluing the

guide rails to the sled board. The 1/8″ spacer strips hold the guide

rails slightly above the top of the table. Use a piece of tape to mark

the center of the saw blade and align the center of the sled board

with this mark. Flush the edge of the sled board with the table edge.

Add some weight to the top and allow the glue to dry.

5. Center the tip of the plywood triangle with the middle of the

saw kerf and against the rear sled fence. The dust bevel on the

bottom edge prevents dust buildup.

6. Screw the T-track and the safety shield in place. Add the stop

block and the sled is ready to use.

7. Cut the first miter with the frame material on the right side of

the miter sled. We marked our miter sled to remind us of the

cutting order.

8. Cut the second miter with the frame material on the left side

of the miter sled. Set the adjustable stop block for the required

lengths.

9. Make a clamping jig to help assemble the frames. Glue and

clamp the sides to the jig base. Make sure the inside of the sides

without threaded inserts are perfectly square to each other.

10. Rub glue on the end grain of your frame parts. Let it dry about

10 or 15 seconds. If it seems to soak in a lot, add a little more glue,

rub again and let the parts rest for another 5 or 10 seconds. When

the glue seems a bit tacky (no longer runny) you can put the parts

in the clamping jig. Note that the filler boards are already in place.

11. Assemble the frame in the clamping jig one part at a time.

Start with a long side (part 1) and add parts 2, 3 and 4 in order.

Line up the miters and you’re ready to apply clamping pressure.

12. Apply clamping pressure a little bit at a time. Turn each clamp

lightly at first. Double-check that the miters are still lined up

and then apply more pressure. When the risk of slippage seems

to be gone, apply firm pressure to the clamping bolts. Don’t

overtighten.

13. Finish your frames. A spray-on finish is the easiest. We bevel-cut a 2×6 in half and

screwed on a piece of plywood at both ends to make a simple finishing rack. The

open design allows the overspray to blow through rather than bounce back onto the

frames. Replace the masking tape when it gets covered with finish. |