We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Whether you shop is large or small, mobile bases allow you to get the most out of the space you have. When I need to re-saw some long stock on my bandsaw, its mobile base lets me easily reposition it to clear nearby obstacles. When I’m done, the bandsaw goes back in the corner where it doesn’t take up precious floor space. Some folks have mobile bases in order to get the car in the garage. Others like them because they make cleanup easier. Whatever the size of your shop, mobile bases make it a better place to work.

Custom & Universal Bases

Custom bases are built to fit specific machines. For more on custom bases, see “Custom Bases,”. Universal bases are the category we chose for this test. Because these bases change as your tools change, they can keep up with the evolution of your shop. They’re capable of handling most home shop tools (see table, for typical shop-machine weight ranges).

The Test

We loaded each base to 400 lbs. since most stationary tools fall under this weight limit. The Delta was loaded to its 300-lb. limit. Bases capable of carrying more were re-tested at their weight limits. We looked at each base for ease of transition from rolling cart to stationary platform and effort needed to level them on an uneven floor. We noted how stable each platform was in the down position as well as how maneuverable it was in tight spaces.

What To Look For in a Mobile Base

Mobile bases work best on smooth floors free from large bumps and debris. The best base changes quickly and easily from a solid platform to a highly maneuverable tool dolly. At rest, a mobile base needs to be steady. You don’t want your tablesaw to start sliding across the floor in the middle of a cut. And when you’re done, you want it to glide easily back to it’s nesting place.

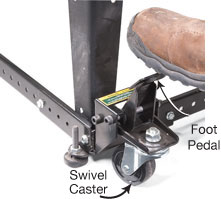

Lever-Action vs. Foot Pedal vs. Screw-Down

The lever-action on the Vega bases and the foot-pedal of the General, Delta and Rockler were the easiest to transition between mobile and stationary modes. These bases are a good choice for machines that get moved every time they’re used. The screw-down footpad found on the Shop Fox models automatically adjusts for an uneven floor. Bending over to screw down each foot is a bother, though, making the Shop Fox a better choice for infrequent moves on an uneven floor.

PHOTO 1: |

PHOTO 2: |

Prose

The base is easy to adjust and can be assembled right under the machine (Photo 1). The “jack and trolley” system is as quick and easy as it gets when moving from a resting position to a mobile one (Photo 2). The ability to steer with the double wheels at the base of the handle makes it a dream to maneuver. The Vega is more stable in transit because any pushing or pulling force is on the base, not on the machine. Also, the lift ring can be positioned right on the center of gravity of the machine, not the base. This is a real benefit when moving machines like bandsaws whose center of gravity is way off center. When you remove the handle, the base rests on the four 1/16-in.-thick steel corner pads. It’s as though your machine were sitting on its own four feet. No weight is left on the wheels. This makes a very stable platform that won’t budge and does not change the height of your machine. A separate leveler (Photo 3) takes care of uneven floors.

Cons

You have to keep track of the handle and the leveler with the Vega. And floor clearance is low by the fixed wheels.The General is our Best Buy because it offers the best stability, mobility and capacity for the price.

PHOTO 3: |

|

The General offers a convenient foot-pedal design. Each swivel caster has a foot pedal that raises and lowers the base with little effort. The transition from a stable platform to a mobile base is a breeze. |

|

Prose

We really like the quick and easy foot-pedal lift (see inset photo). The General is capable of carrying big machines like cabinet saws and 8-in. jointers. And the General comes at a price that’s hard to beat.

Cons

More than 100 parts make assembly and size adjustments time-consuming. You have to stoop over to adjust the footpads on an uneven floor.

The Craftsman features red wheels on what appears to be an HTC base. |

The HTC 2000 is the original design that spawned a number of look-alikes. |

Prose

This style of base is stable when down and, when up, wheels with ease, even with a full load.

Cons

In the 300- to 400-lb. range, we found the cam levers to be undersized for the job. We had to lift up on the machine to help raise the base off the footpads. With over 100 parts to put together, these models require considerable time to assemble and adjust.

These bases are an excellent choice for smaller, lighter machines that get moved a lot. The Rockler is the one to pick for an uneven floor. That’s because it lifts the footpads 3/8 in. higher off the floor than the Delta.

The Delta 50-345 is an old workhorse. The single-pedal design is hard to beat for ease of use and mobility. It has a realistic 300-lb. weight limit. |

The Rockler 92051 features a removable caster. Two thumb screws allow it to be moved from base to base. You save money because you only need one kit with the caster. |

Prose

The single-pedal design is quick and easy to operate. These bases can be custom fit to any size machine within their weight limit.

Cons

Assembly involves extra time and money because you provide the 1-1/2-in.-square hardwood rails. The wood rails tend to flex as the foot pedal is pushed down to raise the base. The condition is aggravated under heavy loads or when the pedal is mounted on a long rail.

The Shop Fox bases are among the strongest mobile bases for the money. All three models feature screw-down footpads.

Shop Fox bases feature two screw-down footpads that secure the base to the floor. The screw-down feet are great on uneven floors, but are tedious to operate. |

|

Prose

The bases are capable of supporting their enormous maximum-weight claims. The stiff frames provide a stable platform in transit.

Cons

The bolts that hold the steel tubes together are tightened into very shallow threaded holes in the smaller rails. If you’re not careful, it’s easy to strip out the threads. The Shop Fox bases are noticeably harder to push and maneuver than the other models. When you load one over 600 lbs., it is very difficult for one person to move.

Shop Fox bases feature two screw-down footpads that secure the base to the floor. The screw-down feet are great on uneven floors, but are tedious to operate. |

|

Prose

Assembly is literally a snap (see photo). The Jets have easy-to-use foot-operated locks on the fixed casters.

Cons

The swivel casters have small lever locks on the wheel hubs that can be hard to reach. The locks are ineffective because they don’t prevent the wheels from swiveling. This is one of the least stable bases we tested.

Custom Bases

Custom bases are well-built, expensive and designed to fit specific machines. Their strength comes from the welded tubular steel frames. They come ready to go right out of the package, so you have no assembly hassles. These bases cost from $80 to more than $200. The fact that they only fit certain machines means if you change machines you may have to buy a new base. We tested some custom bases by HTC, DeWalt, Delta and Jet. They all performed well. The Delta and DeWalt were tops for ease of transition with their single foot-pedal for raising and lowering the base. The HTC and Jet are very similar in design. Both offer high floor clearance, screw-down wheel locks and a three-point stance that are real assets on uneven floors.

|

|

Getting The Cutting List

Sources

Craftsman, (800) 377-7414, www.sears.com/craftsman, Delta International, (800) 438-2486, www.deltawoodworking.com, General International, (514) 326-1161, www.general.ca, HTC, (800) 624-2027

Jet Equipment, (800) 274-6848, www.jettools.com, Rockler, (800) 279-4441, www.rockler.com, Shop Fox, (800) 840-8420, www.shopfoxtools.com, Vega Enterprise, (800) 222-8342, www.vegawoodworking.com, Woodcraft, (800) 225-1153, www.woodcraft.com.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.