We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Veneer for Edging

Instead of buying veneer or edge-banding material for plywood, make your own from scrap left over from the project. This is not only inexpensive, but the edge banding will match exactly.

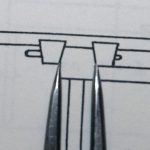

First install a zero-clearance throat plate on your tablesaw. Take a long piece of scrap plywood and rip pieces 1/8" wider than the thickness of the plywood. Turn the strip on edge and move your tablesaw fence towards the blade until the plywood face veneer is just to the left of the blade. Rip the face veneer from the plywood. Repeat the process for the other side of the plywood strip. Glue on and trim to fit.

Gregg Kerber

My Take

Now that's thrifty! For a large project with lots of edge banding, maybe not, but it sure beats buying a 200 foot roll of edge banding for a project that only requires about 10 feet!

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.