|

You can find a place for every

conceivable sewing notion in this

Shaker-inspired chest of drawers.

Mix 'n' match modular trays fi t perfectly

in the middle drawers. Store patterns or

magazines in the large lower drawer.

There’s enough compartments for a

complete sewing kit.

You’ll make the most out of your

router and half-blind dovetail jig when

you build this cabinet. Not only are the

drawers dovetailed, but the case is as well!

All the joints are modern variations of the

dovetails made by Shaker cabinet-makers

150 years ago.

Tools and materials

In addition to a standard set of power tools, you’ll need a halfblind

dovetail jig and a biscuit joiner. Any brand of jig will do.

I’ve based the dimensions of this case on the dovetails made by

a Porter-Cable jig. You’ll have to slightly alter the Cutting List, below, if your jig cuts wider or longer dovetails (see "Changing

Dimensions to Suit Your Jig", below). A router table

makes cutting the casework dovetails a lot easier.

The chest requires about 25 bd. ft. of 4/4 primary wood and

25 bd. ft. of 4/4 secondary wood. I used cherry and yellow poplar. The modular trays for each drawer are

made by Rubbermaid and are available at sewing centers

nationwide. I bought the drawer

pulls from a company that specializes in Shaker reproductions

(see Sources, below).

The sides

Be a stickler for fl atness throughout this project, particularly

when you mill and glue up the sides. You’ll go nuts trying to

fi t dovetails in cupped or warped boards.

Begin by making the case; then build the drawers to fit.

(Here’s a woodworking truism: “Always make the holes first,

and then the parts that go into them!”) Start building the case

by milling and routing the sides. They’re split in half because

they’re too wide to fi t into a standard dovetail jig.

Mill the wood for sides B1 and B2. Cut them to width and

length, and mark the front and top. Avoid sapwood on the

front edge.

Next, mill the top rails C, dividers D and supports E. They’re

all the same thickness. (Make a few extra supports E as test

pieces.) The parts that show in the front of the case (C1 and

D1) are made from cherry, while those that don’t show (C2 and D2) are made from yellow poplar. Rip all

parts C and D to width, and then cut

them all to the same length.

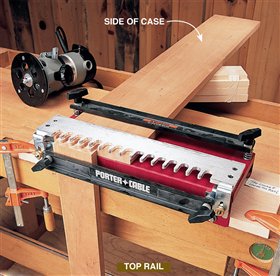

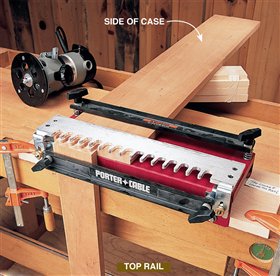

Set up your half-blind dovetail jig and

cut dovetails in the sides and top rails

(Photo 1). The two pieces aren’t the

same width, so chances are you’ll cut an

extra socket in the side. No big deal. It

won’t show.

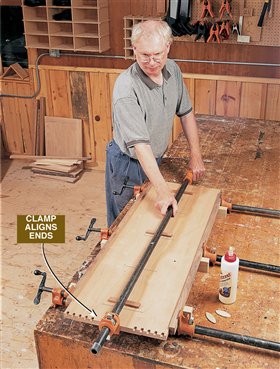

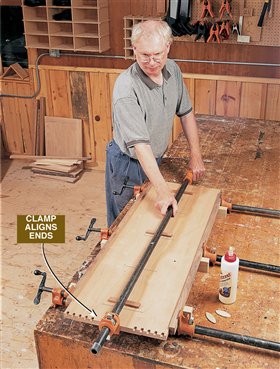

Join the sides together with biscuits or

splines (Photo 2). Glue the sides with

the help of one long clamp to align the

ends (Photo 3).

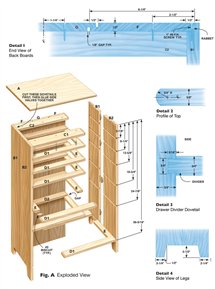

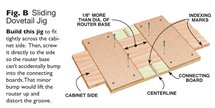

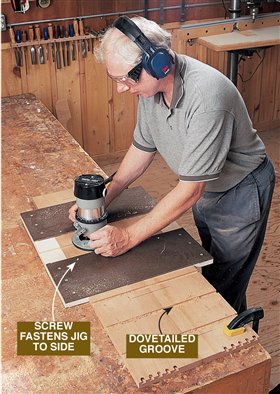

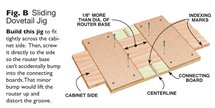

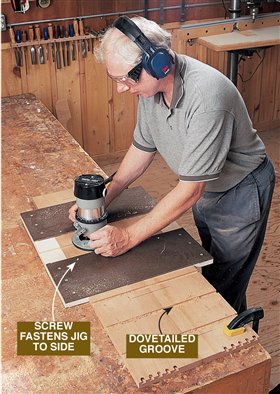

Now, make sliding dovetails to hold

the drawer supports (Fig. A, Detail 3). Begin by laying out the centerlines of

each dovetail on the outside face of a

side (for the dimensions, see Fig. A).

Then make a jig for your router (Fig. B)

and have at it (Photo 4). I screwed the

jig to the side for the most consistent

results. This pays off when you fit the

supports and dividers to the dovetailed

slots. Don’t mind the screw holes.

They’re on the inside of the cabinet, after

all.

Lastly, rabbet the rear edges of the

sides to hold the back (Fig. A, Detail 1).

Saw out the legs on the bottom of the

sides (Fig. A, Detail 4).

Rails, dividers and supports

Every one of these pieces is dovetailed in

a different way, but don’t worry; setting

up your router to make safe and accurate

cuts is easy.

You’ve already cut half-blind dovetails

on the top rails C, but with the rabbet cut

for the back boards, rail C2 has to be

ripped about 1/2" narrower. The back

boards sit on top of the rail and are

screwed into it, so cut the rail just enough

to match the rabbet (Fig. A).

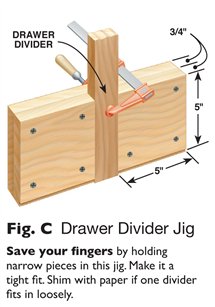

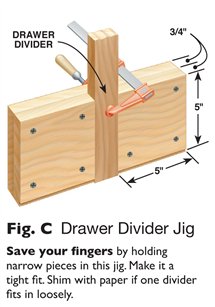

Dovetail the ends of each divider D on

a router table (Photo 5). It’s dangerous to

hold such a narrow piece on end by itself,

so make a jig to hold it (Fig. C). Setting

up the cut is kind of fussy (Fig. D), so

chew up your test pieces before cutting

into the good stuff. The length of the

router-table dovetail must exactly match

the length of the dovetails you made with

the half-blind jig. No problem. Set the

height of the bit in the router table

directly from the dovetailed end of one of

the top rails C.

Cut sliding dovetails on the drawer

supports E with the same setting on the

router table (Photo 6 and Fig. E).

Cut biscuit slots in the ends of the supports

E and dividers D1 (Photo 7). Mark

the top sides of both parts so you won’t

accidentally fl ip one during the glue up.

A spline or tongue-and-groove joint made

on the router table would also work here.

Assembly

Gluing up the case is quite easy because you only add one

divider at a time. Plus, you won’t need dozens of clamps! The

divider’s dovetailed ends hold themselves in place.

Begin by inserting (without glue) a few of the dividers D1 and D2 to square up the case. Then, glue the top rails C1 and

C2. Glue each of the front dividers D1, starting at the top

(Photo 8).

Leave the lowest rear divider D2 in place and remove the

others. Now you have room to glue supports E to the front dividers D1 (Photo 9). Clamp the supports to the divider.

Finally, glue all the rear dividers D2. Make sure their outer edge is flush with the bottom

of the back board rabbet. There’s a gap between the back of support E and each divider

D2 to allow for wood movement of the case sides (Fig. A).

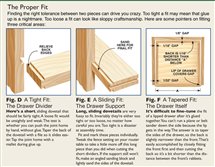

Changing Dimensions

to Suit Your

Dovetail Jig

You’d think all half-blind dovetail

jigs would cut the same size

dovetails, but they don’t. Both

their length and width vary from

jig to jig. We’ve based our Cutting

List on the dovetails made

by a Porter-Cable jig. They’re

5/16" long and spaced 7/8" on

center. Here’s what to watch

out for if you’re using a different

dovetail jig:

– Drawer thickness. Longer

dovetails require a 13/16"

thick front so they don’t cut

into the drawer lips. Make the

rabbets 7/16" deep.

– Drawer sides. The

upper half-pin may not work

out. Change the width of the

drawer parts to get a balanced

look.

Our case and drawers are

dimensioned to fi t Rubbermaid

modular trays. If you want to

use these trays, but cut your

parts on a different jig, pay

attention to these details:

– Length of rails and

dividers. The width of the

drawer opening is fi xed. So the

distance between the dovetail

shoulders is fi xed, too ( it’s

noted in the Cutting List).

Change the overall length of the

rails and dividers to suit your

dovetails.

– Length of drawer

sides. Longer dovetails will

reduce the inside depth of the

drawer. Compensate by adding

length to the drawer sides.

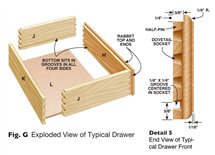

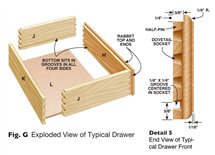

Drawers, back and top

See "Making Lip Drawers with a Dovetail Jig" for complete how-to instructions.

Fit the drawers to the case. There should be 1/16" clearance between the tops of a drawer

side and the divider above it (1/8" for the big drawer).

The drawers have trapped bottoms (Fig. G). I used tempered hardboard for the bottoms

because it’s inexpensive and doesn’t show once the drawer is full. You could use

hardwood plywood instead. I’ve dimensioned the drawers so there’s a half-pin showing

at the top and bottom (Detail 5). Note in the Cutting List, that the back of each

drawer is 1/16" narrower than the distance between the rabbets in the front (Fig. F).

This kind of tapered fit helps drawers slide smoothly, in any project.

Drill holes in the center of each drawer front for pulls. You could turn your own, but

I found some high-quality mail-order pulls that look terrific (see Sources).

Drill holes through the top rail C1 for the screws that hold the top (Photo 10). Make the top and shape its edges (Fig. A, Detail 2) by taking two passes

with a 3/4" round-over bit (see Sources) or one pass with a halfradius

bullnose bit on the router table. Fasten the top to the case.

Make the backs and screw the boards to the case, rails and

dividers (Fig. A, Detail 1). They’re not glued together.

Apply a wipe-on varnish or brush on an oil-based varnish.

I used Minwax Antique Oil on our lightly fi gured cherry, and

it looks great. Give the cabinet some sun and it’ll slowly darken

to a beautiful color.

Sources

Smith Woodworks & Design, niceknobs.com,

908-832-2723, Shaker-style pulls, #SO118, cherry, $1.53 ea., min. order of 10.

MLCS Woodworking, mlcswoodworking.com, 800-533-9298, 3/4"

radius round-over bit, 1/2" shank, #8656, $21; Half-radius bullnose bit,

1/2" shank, #8884, $17.

Cutting List

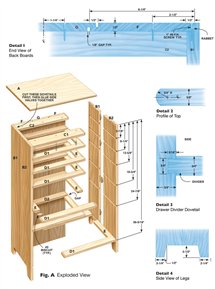

Fig. A: Exploded View

Fig. B: Sliding Dovetail Jig

Fig. C: Drawer Divider Jig

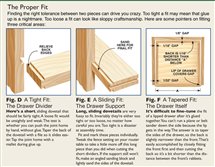

The Proper Fit: Fig. D, Fig. E., Fig. F.

Fig. G: Exploded View of Typical Drawer

This story originally appeared in American Woodworker December 2000, issue #84.

December 2000, issue #84

Purchase this back issue.

|

|

Click on any of the images to view a larger version

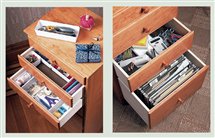

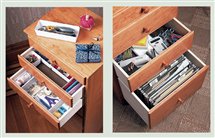

Cabinet of a hundred uses. We designed the

drawers so modular

plastic trays found

at most sewing

centers (left) fit

perfectly with no

rattling around.

Plus the bottom

drawer is just the

right size for file

folders to keep

patterns organized.

Office supplies

(right), fly-tying

gear—you name

it—this cabinet can

organize tons

of stuff.

1. Cut dovetails in the sides and top rails. Each side of the

cabinet is composed of two pieces that are glued together

after the dovetails are cut because the complete side is too

wide to fit in a basic dovetail jig.

2. Cut biscuit slots in each half of one side. Use biscuits or

splines to align the two halves when you glue them together.

3. Glue the side together. Align the ends with a clamp

placed lengthwise. With biscuits in the glue joint, you’ll need the

force of a clamp to shift the boards. Once the ends are aligned, remove the long clamp and check

the side for flatness. Flat sides are necessary for the next step

to succeed!

4. Rout dovetailed grooves in the

sides. Align the jig (Fig. B) with center

marks on the edge of the side. Screw the

jig directly to the side; the screws will

hold down the far side of the jig, where

clamps can’t reach. The screw holes are

invisible in the fi nished case.

5. Cut dovetails in the ends of the

dividers. Rout equally from both sides of

the divider so the dovetail is centered.

Clamp the narrow workpiece to the jig

so it doesn’t slip down into the opening

of the router table.

6. Dovetail the drawer supports. It’s basically the same

setting as in Photo 5. You may have to move the fence to cut a

fraction deeper, because the fi t over a longer distance needs to

be looser (Fig. E).

7. Cut slots in the ends of the drawer supports for #0 biscuits.

Line up all the supports and make, in effect, one continuous slot.

Biscuits align all the pieces that support the drawer so the drawer

will slide smoothly, without hitting any uneven edges.

8. Assemble

the case

one piece at

a time. That’s

the beauty of

dovetails! You

don’t have to

clamp a dozen

pieces at once.

9. Glue the drawer supports to the front dividers. The

drawer supports are only glued at the front, not in the groove,

so the case side is free to expand and contract.

10. Drill screw holes for the top from inside the case. That way

you know the holes will be accessible when you install the top.

|