We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

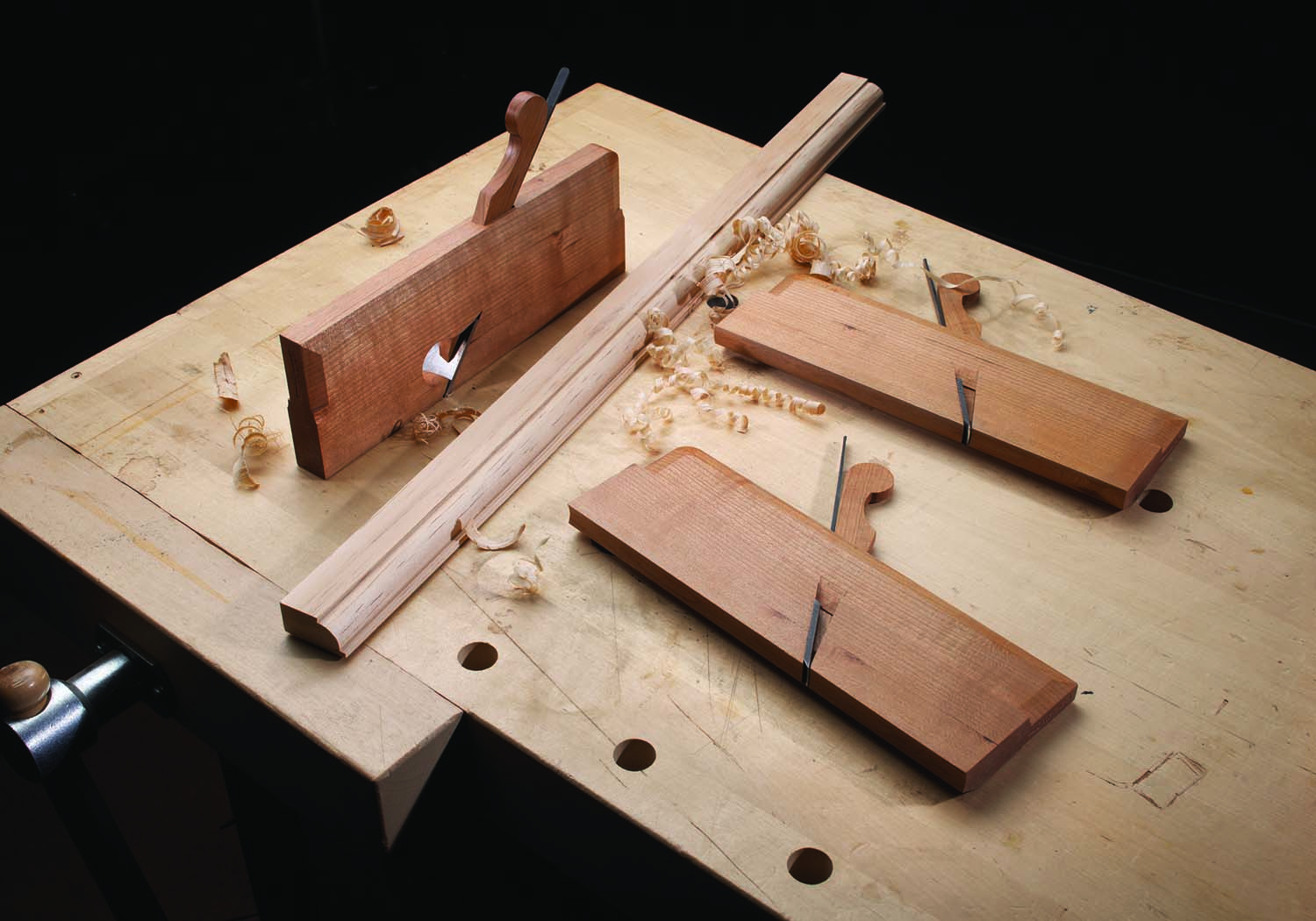

Making mouldings. Short runs of mouldings are easy to make with these planes. And here’s a bonus: No more sanding mouldings.

Editor’s note: This article was originally published in the December 2010 issue of Popular Woodworking.

Vintage moulding planes are tricky beasts. Typically the wood is warped, the irons are misshaped and the wedges are beat to snot. So it’s no wonder that people struggle with the tools.

This year Matt Bickford became a full-time planemaker to help supply woodworkers with moulding planes that work like they should. Bickford is a long-time woodworker and a former derivatives trader who gave up the world of high finance to build planes in his basement shop, mostly by hand and with incredible attention to detail.

This year I purchased some of his tools and have been building furniture with them. I am impressed.

His tools look similar to the British moulding planes made by Clark & Williams of Eureka Spring, Ark. That should come as no surprise because Bickford learned to make the tools from the company’s excellent DVD on the topic.

But there are some differences. Bickford offers his tools in both beech and cherry. Beech is the traditional wood, but I tried out the cherry ones. I found cherry to be entirely suitable for this form of tool. Bickford also offers his simple rabbet plane with one corner boxed in persimmon. This hard corner offers you a great way to start a moulding using only a simple gauge line. Very nice.

Look close. The details on Bickford’s planes are crisp and executed mostly by hand. Nice.

The irons in Bickford’s planes come from Lie-Nielsen Toolworks, so you know the steel is excellent.

As far as fit and finish go, I would say that Bickford’s are excellent. He’s not quite up to the level of Clark & Williams (which is a totally insane level of perfection), but they are better than much of the vintage tools out there. And the young Bickford has many years of planemaking ahead of him.

From a user’s perspective, the tools are a dream. They come sharp (really sharp) and ready to put to work. The throats are tight to reduce tear-out. The wedges fit nicely and hold the irons tight to the 55° bed.

But most of all, these planes give you the freedom to make any moulding you can conceive of. You don’t need hundeds of router bits or crazy jigs – just a few moulding planes, a rabbet plane and a nice cutting gauge.

If you are looking to get started in moulding planes, you also should check out Bickford’s “starter set” of moulding planes, which actually will probably be enough for most woodworkers for a lifetime.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.