We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

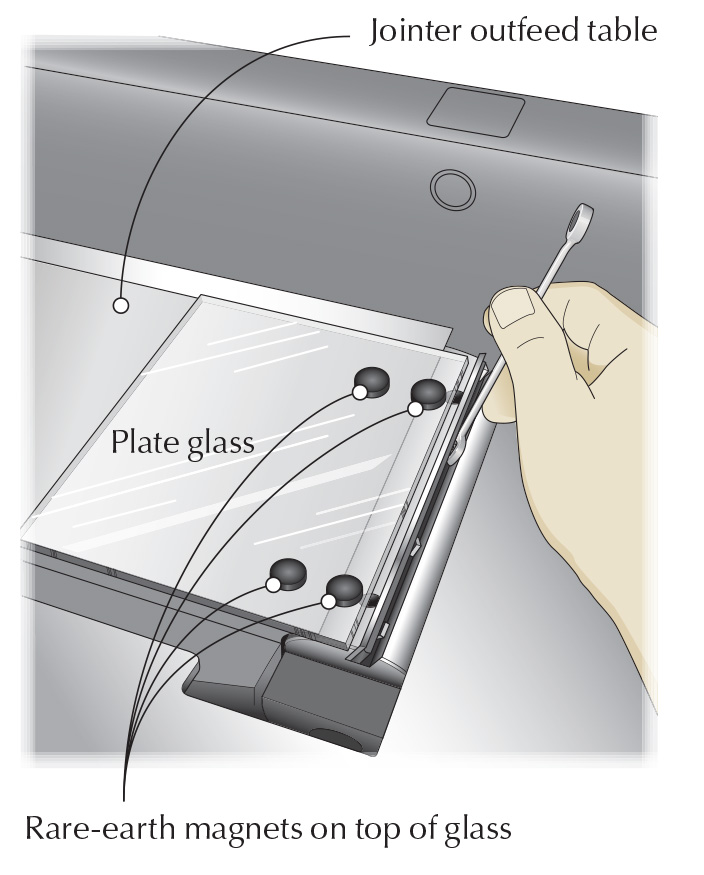

A piece of thick plate glass is dead flat and it’s easy to use to align standard jointer knives that have gib screws. A couple of rare-earth magnets secured to the glass with double-sided tape keep it flat on the jointer’s outfeed table. Two more magnets on the glass over the cutterhead serve as an alignment tool for setting the blade height.

To use the jig, slightly lower the jointer infeed table to make it easier to access the cutterhead, then remove the first dull knife. Set your replacement blade loosely in its cutterhead slot, then slowly rotate the cutterhead until the sharp edge of the new knife reaches the apex of travel. The glass plate, positioned on the outfeed side of the jointer, is then pressed onto the top edge of the blade where the magnets grab and hold the knife edge against the bottom of the glass. To complete the installation, tighten the gib screws. The process is repeated for the remaining blades.

The glass and magnets not only establish the blade height flush to the outfeed table but also keep the knife flat and true across the width of the jointer’s outfeed table. With all the knives changed, raise the infeed table to the desired height for a test cut. –Brian Mayeaux

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.