We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Occasionally while woodworking, we all find the need to work on tapered parts. But how do you hold those parts in a vise or with a clamp in order to do the work?

Occasionally while woodworking, we all find the need to work on tapered parts. But how do you hold those parts in a vise or with a clamp in order to do the work?

I saw a product in a catalog that used the age-old concept of a pivoting jaw mounted to a sphere to clamp a tapered piece. It occurred to me that I might be able to use some type of ball to make a similar device in my own shop. After careful consideration, I decided to try a golf ball.

At first, I considered cutting the golf ball in half to mount it to a block of wood using a screw, glue or both. Cutting a golf ball in half seemed rather dicey considering that some golf balls have liquid centers under pressure, so I had to find another solution.

I’m not a wood turner, but I recently saw a jig for turning a sphere where the ball was held in place by friction. The jig basically consisted of a piece of wood with a hole slightly smaller than the diameter of the sphere to be turned. The partially turned ball is jammed into the hole then turned to completion in the “jam chuck.”

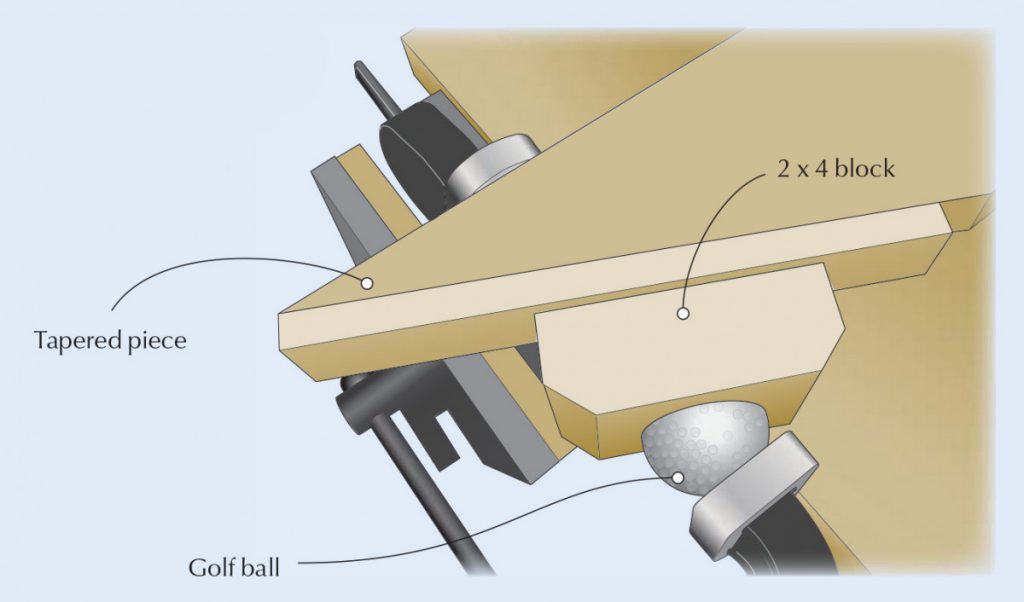

Taking the concept and applying it to my needs, I measured the golf ball and decided on the dimension of the hole that I thought would work best. I used a 1 5⁄8“-diameter Forstner bit to drill a hole 3⁄4” deep into a piece of 2 x 4 stock.

The golf ball was then pressed into the hole with a clamp. It worked like a charm to securely hold the sphere in place. I found that the resiliency of a golf ball is very forgiving. It held tight in the hole; no glue required.

To improve the grip of the jig, I attached a piece of #220-grit sandpaper to the back of the block using double-sided tape.

By putting together the two concepts – pivoting on a ball and holding the ball in a jam chuck – I came up with my version of a taper-clamping device. Now I’m more than ready to take on projects that require clamping tapered parts, or even compound-tapered parts. –John Cusimano

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.