We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

When I rough out work on the band saw, I often find little pieces getting stuck in the throat insert or the split in the table. Also, I find that work can catch in the miter slot. So, I made an auxiliary table to solve these problems.

When I rough out work on the band saw, I often find little pieces getting stuck in the throat insert or the split in the table. Also, I find that work can catch in the miter slot. So, I made an auxiliary table to solve these problems.

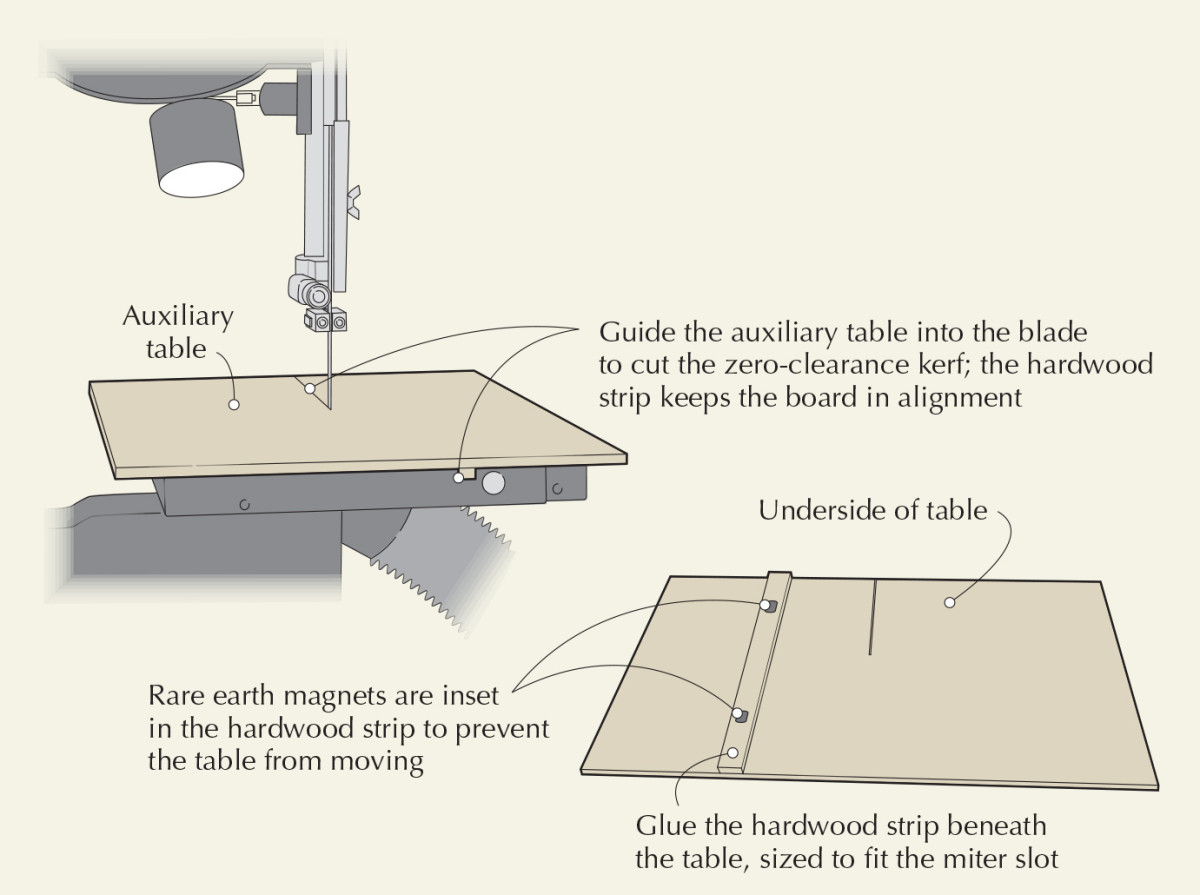

I used a sheet of 1⁄4“ particleboard that is coated on one side with melamine (the minimal thickness reduces the amount of lost resaw capacity), but you can use 1⁄2“ or thicker material, such as Baltic birch plywood. Size your table according to your needs.

I rounded all the corners and epoxied a strip of hardwood, matching the width and length of the miter slot, to the underside of the particleboard.

To keep the auxiliary table from moving during use, I used a Forstner bit to inset a couple rare earth magnets in the hardwood strip.

Be sure to remove the table when not in use, especially if you’re cutting wet wood. Clean and wax the cast iron table to prevent rust from developing. –Will Simpson

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

![Bringing the 1955 Crescent Band Saw to Life! [Video]](http://www.popularwoodworking.com/wp-content/uploads/bfi_thumb/dummy-transparent-olcy6s63it1p9yp7uhusjas7c8kahafrhg9su7q9i0.png)