We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Spread open the pages of most woodworking magazines, including Popular Woodworking, and you’ll find projects built using face frames. Woodworkers go about building face-frame projects in varying ways.

Spread open the pages of most woodworking magazines, including Popular Woodworking, and you’ll find projects built using face frames. Woodworkers go about building face-frame projects in varying ways.

Contributing editor Troy Sexton constructs the face frame then builds and fits the cabinet to that frame (See American Cabinet, Popular Woodworking April 2008, issue #168). I tackle a face-frame cabinet from a completely opposite direction. I build the cabinet then design my face frame to fit that case.

The one technique we both have in common is that we build the face frame larger and wider than the cabinet. The frame overhangs the case by at least 1/8″. That’s so we can trim the frame to exactly fit the case. And how do we trim the frame? With a router and a flush-trim router bit.

The next question is which flush-trim bit. Yesterday I received a new catalog from a router bit company. I begin thumbing through the pages and was intrigues by a newly designed flush-trim bit , at least this was the first time I had seen this design. This bit has a glue-reservoir area that bridges a glue line in order to eliminate glue buildup on the bearing. Do we need this feature?

Also, do we need spiral-upcut and downcut flush-trim bits. Router bit manufacturers have touted these bits for years. Spiral flush-trim bits are supposed to provide a cleaner cut. How about downshear flush-trim bits? This style bit has been available for a while. Is this design something we should have in our bit arsenal?

For years, I’ve used a basic, straight flush-trim bit and it’s served me fine. I guess I’m set in my ways because I don’t see the need for these somewhat specialized router bits. I’m not saying that the next time I need to replace my flush-trim bit I’ll stay with my old standby, but I’m perfectly satisfied with the job the basic bit is doing.

So, how do you trim face frames to the case? Do you have a favorite flush-trim router bit or technique for flushing the face frame to the cabinet? Leave a comment and let us know how you’re trimming frame-to-cabinet joinery.

Oh , and a tip I picked up from Troy was to always do my flush trimming using a climb cut. That technique keeps you from ripping out the wood as you trim. That’s what makes the results using an ordinary flush-trim router bit equal to the newer designs.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I have always built cabinets first, then the face frame. I use a straight bit to trim the frame. I consider "climb cuts" dangerous but have used them on occasion to get a job done right. In some given situations they are the best way. Spiral up/down cuts I have never tried in face frame trimming. I do use them for one method of mortice construction.

A better more detailed explanation is here:

http://www.newwoodworker.com/clmbcuttng.html

I said, "against the rotation" and probably should have said "usual rotation" vis-a-vis the wood which is against the spin. Think of it like this, usually the bit is spinning like a tire backing up; with a climb cut you are moving the router in a direction where the bit is like a tire spinning at 5000 RPM in the direction you are trying to control – there lies the danger.

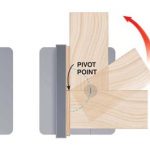

Climb cut = Moving the router or the stock in such a way that it against the rotation of the bit. For example, if you are using a handhaled router to treat an edge, you move the router from left to right normally. With a climb cut, you would go from right to left. This lessens the chances of tearout and chipped edges, but it can also be much more dangerous.

Even with the "backing the router bit into the cut" comment, I still don’t know what a climb cut is. Could someone provide a more complete description? Thanks!

I build face frame cabinets in a similar way, but with

one minor change: I am not very good at keeping the router

steady on a thin rail or stile, so I use a sub-base on

the router that can span the width of the cabinet. It

almost looks like a trammel for cutting circles. With

the sub-base reaching the other side, the router can’t

tip on me.

I also have used a block plane with good results as

well, but you have to be careful not to tear things out.

I like to skew the plane at an angle for a cleaner cut.

Chris

Yes, I too build face-frames larger than required for a cabinet and then trim it to fit. I also don’t worry about new router-bit designs that are touted as better than last year’s models – I use a handplane.

I used climb cuts for years without knowing what they were called. When I read about climb cuts I had to learn more — and realized I already knew what they were.

Why are they called climb cuts and is there any better terminology out there that actually makes sense? Something like "backing the router bit into the cut?"

regards,

Dave