We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Bandsawing long boards without a helper is tricky business. I don’t like roller stands. Most aren’t tall enough for a bandsaw. Also, if your stock butts into the roller instead of riding over it, the stand can tip over. So I made this detachable outfeed table. When not in use, it lifts off the saw (no tools needed) and folds flat for storage. It’s plenty sturdy. I’ve used it to cut straight sides on large burl slabs weighing over 100 lbs with no problem. The outfeed table is attached using a “French cleat”, typically used for hanging cabinets without screwing into their backs.

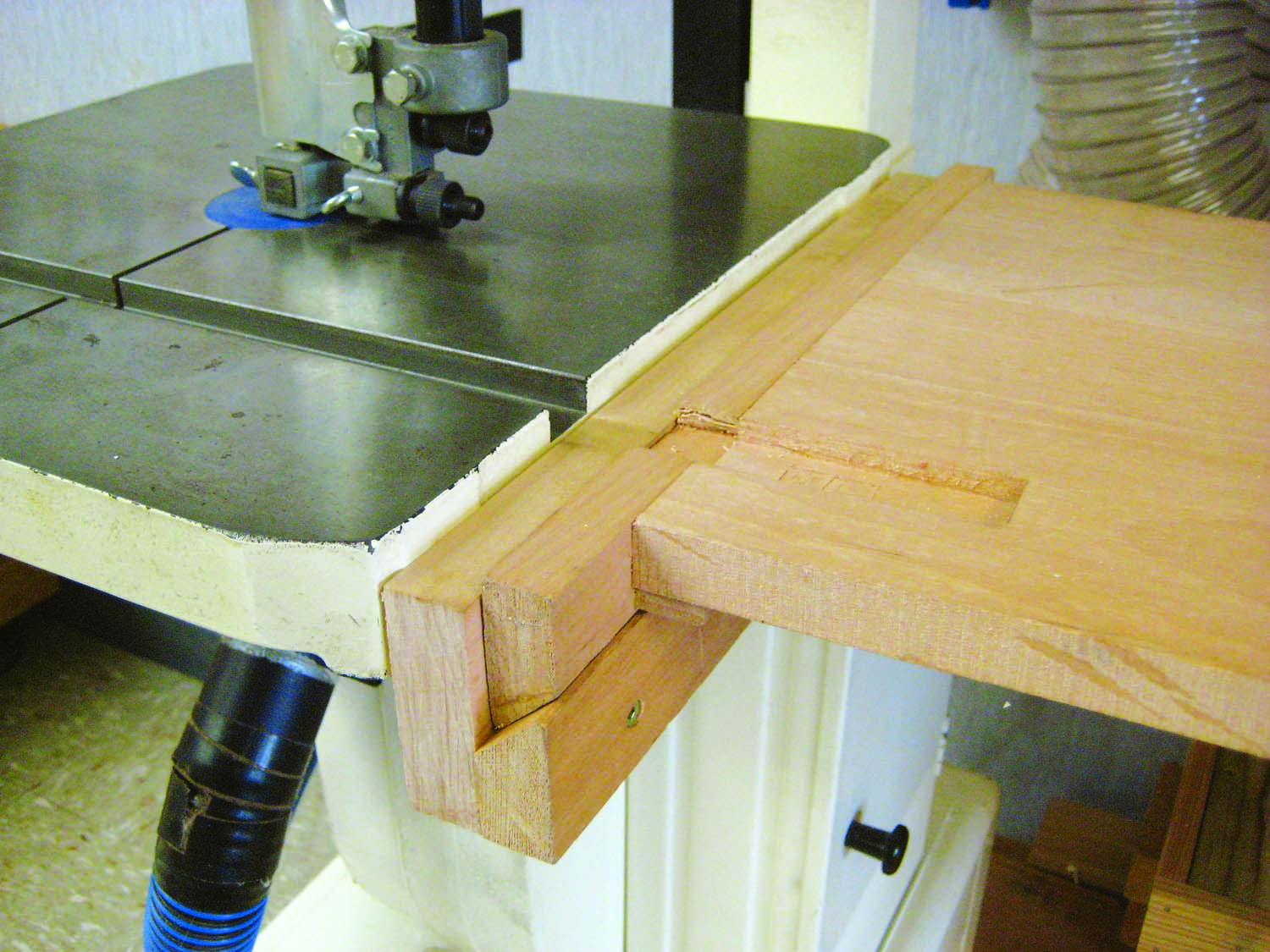

Here’s how it works. Attach a cleat with a 45° angle to the back side of your bandsaw’s table. If your saw’s table doesn’t have any pre-drilled holes along its back edge, you’ll have to drill a couple. Attach a mating cleat to the underside of the outfeed table. The weight of the outfeed table holds it in place. Size and position your cleats so that the outfeed table’s height is flush with your bandsaw’s table.

At the far end of the outfeed table I attached a leg using two hinges on the outfeed’s underside. A chain keeps the leg from rotating out too far. I also routed a groove into the outfeed table to extend the slot for my saw’s miter gauge, if needed.

If you’re using a shop-made bandsaw fence that clamps to the front and back of the saw’s table, you’ll have to modify it, so it clamps to the left hand side of the table. -Rand Hall

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

![Bringing the 1955 Crescent Band Saw to Life! [Video]](http://www.popularwoodworking.com/wp-content/uploads/bfi_thumb/dummy-transparent-olcy6s63it1p9yp7uhusjas7c8kahafrhg9su7q9i0.png)