We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

We may receive commission when you use our affiliate links. However, this does not impact our recommendations.

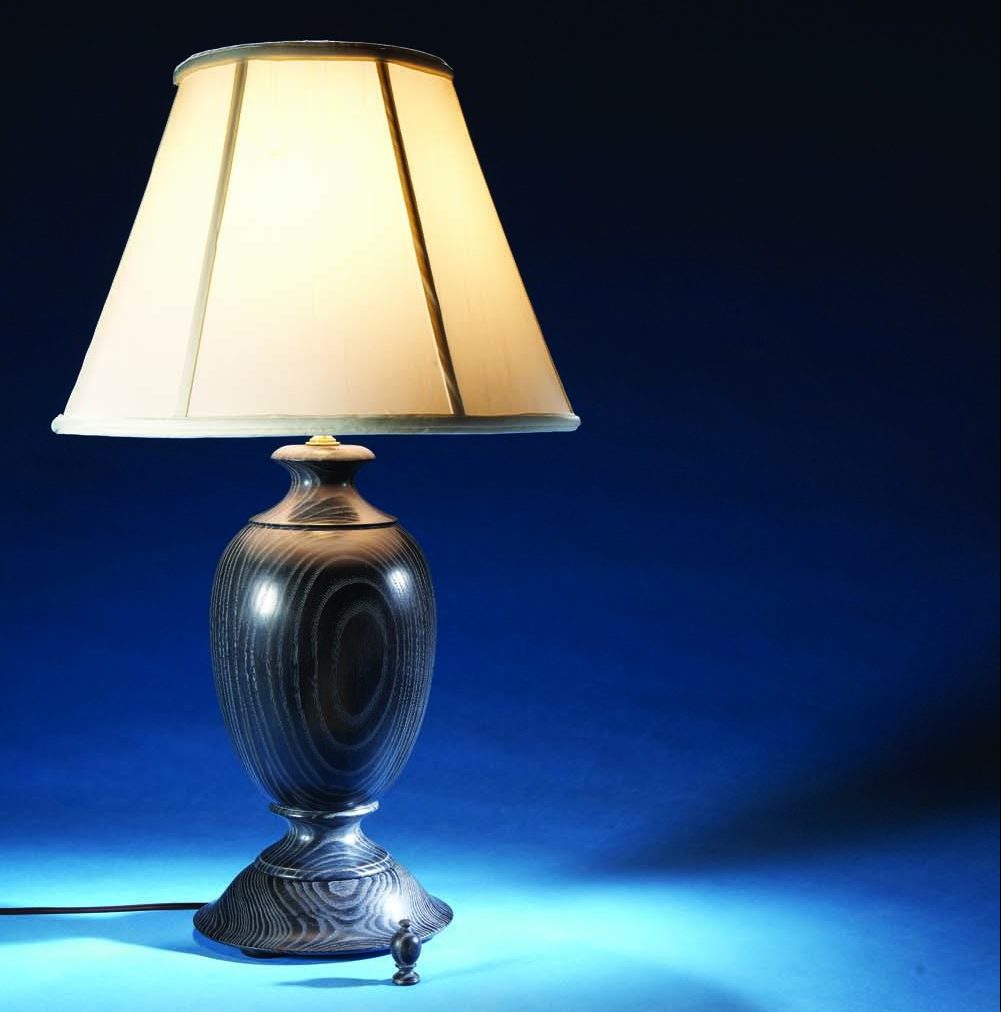

Whether shaped as a vase, a column or even an egg, there’s plenty of room for expression in a turned lamp. The flowing contours of the lamp shown here do more than make it an attractive project. Learning to shape these pleasing convex and concave forms is an excellent skill-building challenge for turners of all levels. Similarly, applying this lamp’s eye-catching finish encourages thinking beyond stain and varnish.

You’ll need a 1/2″ or 9/16″ detail/spindle gouge to shape the lamp’s contours. You’ll also need a 1/4″ parting tool, a 1/2″ or 5/8″ skew chisel, a 1-1/4″ to 1-3/4″ spindle-roughing gouge and a pair of outside calipers to set the diameters. If you turn a finial, you’ll need a 1/4″ detail/spindle gouge to shape its tight coves.

The harp, socket, cord and other hardware can be purchased as a kit, online or at any lamp store. And the answer to the inevitable question, “How the heck do I get the hole through the center?” is simpler than you might think.

Initial choices

Your choice of wood is wide open; just make sure it’s adequately dry. Knowing the lamp’s height and diameter before you begin turning is important, because these dimensions affect how you prepare the turning blank you start with and the method you use to drill the hole through the center.

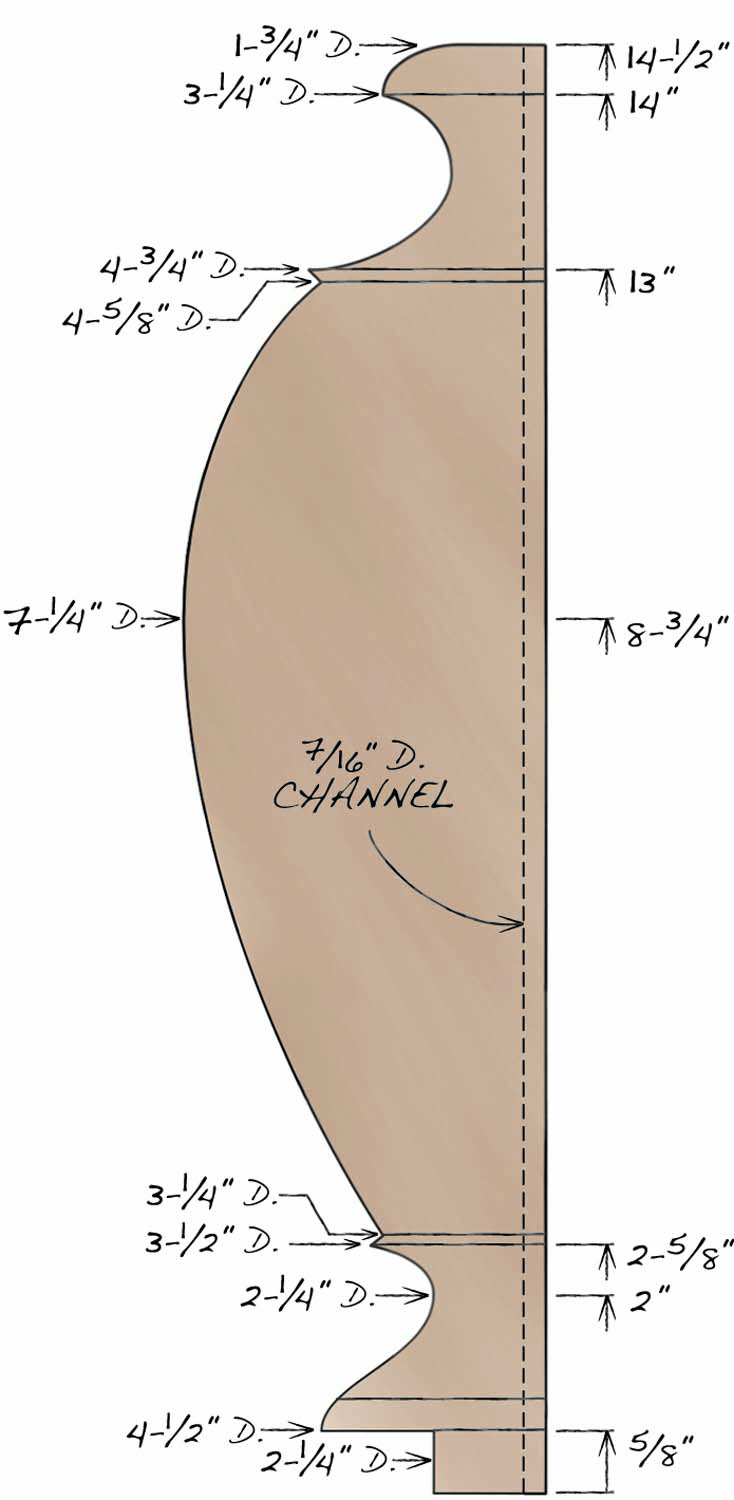

This lamp stands just over 16″ high without the harp and shade. The 7-1/4″ diameter of its body virtually rules out using a blank made from single piece of wood, so gluing up 8/4 stock is the best option. The 8-1/4″ diameter of the lamp’s base is even larger, but because it’s a separate part, it can be turned from a single piece of 8/4 stock. FYI: The diameter of the base is not a minor detail—it’s an important safety feature designed to keep the lamp from tipping over.

Pro Tip: According to UL (Underwriters Laboratories) standards, a lamp must withstand an 8° tip without falling over.

The center hole

Photo 1. Glue the blank together after cutting grooves and installing plugs so the grooves form a channel for the wiring. The plugs also allow mounting the blank on the lathe.

Drilling through the wood to create the center hole is a viable option when the body is relatively short or consists of a single piece of wood (see “Drilling on the Lathe,” page xx). Choosing to go with a glued-up blank almost always makes the job easier. You simply saw or rout centered grooves in the two inside faces of the lamination and install plugs at both ends to create a 7/16″ square channel to house the threaded rod (Photo 1). This method works regardless of the lamp’s diameter or height.

Glue up the blank

Make sure the boards you plan to laminate are flat. Cut the centered grooves 7/16″ wide and slightly more than 7/32″ deep. Then size a pair of 1-1/2″ long plugs to fit. The boards must close tightly together when the plugs are installed.

Spread an even coat of glue on both surfaces of each lamination and glue the plugs flush with the ends of the boards. In addition to aligning the grooves, the plugs are used to mount the blank on the lathe. Standard white or yellow glues work well, although glues such as Titebond III and plastic resin glues have less glue creep. Clamp the blank properly, allow the glue to dry for 24 hours and wait at least another 24 hours before turning. Cut the blank into an octagon before mounting it on the lathe; it’s too massive to mount as a square.

Turn the blank

Photo 2. Turn the blank to a cylinder after sawing off its square corners to create an octagon. Always wear a full-face shield when working with such large mass.

Use a spur center in the headstock and a high quality live center in the tailstock to securely mount the blank on the lathe. Spin the blank by hand to make sure it doesn’t contact the tool rest before turning on the lathe. Then rough the blank into a cylinder using the spindle roughing gouge (Photo 2).

Size the diameters at both ends, using a parting tool and outside calipers. Then locate and size the critical diameters for each detail. However, do not size the coves to their final depth, as this will prematurely weaken the blank.

Photo 3. Turn the lamp’s convex middle section first. Reduce the diameters at both ends Then shape each end by gradually rolling the gouge in the direction of the curve as you cut in.

Shape the large, convex middle form first, using the detail/spindle gouge (Photo 3). To cut with the grain when the blank is oriented as it is here—with its grain running parallel to the lathe’s bed—you must work from larger to smaller diameters. Start to rough out the form by shaping a convex curve at each end. Cut in near the end and gradually turn the gouge toward the end as you push in. Make multiple cuts to complete the form, gradually deepening and refining the overall shape while extending the curves until they meet. The goal is to create a flowing, continuous curve that fully realizes the section’s elliptical egg-shaped form.

Photo 4. Create a deep elliptical cove to form the neck. Cut from both sides to the center. Start with the gouge on its side and gradually roll its flute upright as you cut in.

Next, move to the tailstock end to work the top section of the body, called the neck (Photo 4). Use the parting tool to establish the final diameters, then switch to the detail/spindle gouge complete the details. Save the deep asymmetrical cove for last. Cut in towards the center from both sides. Start with the tool’s flute facing the center and turn it face-up as you cut in. Strive to create nice, flowing curves.

Photo 5. Complete the lamp’s body by turning another elliptical cove at the bottom, just above the tenon that will position the body on the base.

Finish the body by completing its bottom section (Photo 5). Establish the final diameters and rough out the tenon that will be used to mount the body on the base. Then, as before, complete the section’s details and turn its deep elliptical cove. Lastly, use the parting tool and calipers to turn the tenon to its final diameter.

Sand the body to remove any torn grain. Then work through the grits until the sanding marks are gone.

Photo 6. Drill through the plugs at both ends of the lamp. Then use a bell hanger’s bit to clear the center channel.

Drill through the plugs with a 7/16″ bit after removing the lamp body from the lathe (Photo 6). Then make sure the center channel is clear from end to end by running a 7/16″ bell hanger bit all the way through (see Sources).

Turn the base

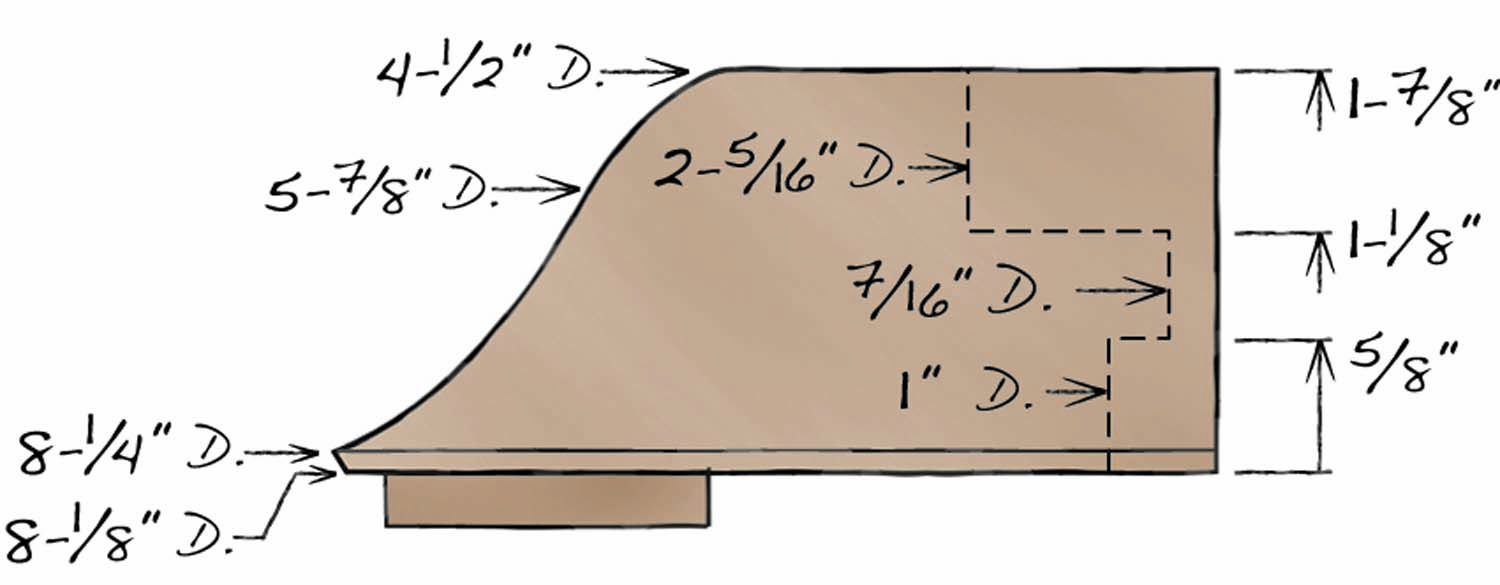

Bandsaw a disc of 8/4 stock for the base and mount it on the lathe using a 3″ dia. faceplate with screws that penetrate about 1/2″ into the underside. Round the disc, level its top surface and roughly hollow the mortise for the lamp body’s tenon to size using the detail/spindle gouge. Then cut straight in with the parting tool to finish sizing the mortise (Photo 7).

Photo 7. Use a parting tool to accurately size the mortise in the lamp’s base. Shape the base’s shallow ogee profile with the detail/spindle gouge.

In this cross-grain construction, the goal is to allow for the difference in wood movement over time, so cut the mortise about 1/16″ larger in dia. than the tenon and slightly deeper than its length. The threaded lamp pipe, secured at both ends, will connect the lamp’s body and base.

Measure the body above the tenon and mark this diameter on the base. Then use the detail spindle gouge to create an ogee curve on the face of the disc from just outside the diameter mark to a point about 1/4″ back from the bottom of the base. To cut with the grain when the blank is oriented as it is here—with its grain running perpendicular to the lathe’s bed—you must work from smaller to larger diameter. So, start the cut from just outside the diameter line and work toward the outside edge. Shaping this reverse curve requires finesse, so take it in stages, refining the look until you’re satisfied.

Complete the turning by cutting a small chamfer on the underside of the base that rises to meet the end of the ogee curve. Finish-sand the base. Then drill a 7/16″ dia. hole through the center, with a 3/4″ deep x 1″ dia. counterbore on the underside. Fasten feet to the underside to raise the base just high enough for the lamp cord to exit.

Apply finish

Photo 8. Apply the distinctive “salt and pepper” finish in two steps. First, brush on a coat of India ink. Then wipe white gel stain into the wood’s pores.

I choose ash for this lamp because it looks great with my “salt and pepper” finish (Photo 8). Brush India ink onto the body and base (see Sources). Let the ink dry for an hour or so. Then wipe on white gel stain (see Sources) and immediately rub it off, working across the grain, so the white color remains only in the pores. Allow adequate drying time. Then reapply the gel stain if the pores aren’t sufficiently filled. Apply your favorite topcoat to protect the finish.

Final assembly

A lamp kit includes all the metal and electrical parts you need to complete the lamp, along with instructions for assembly and wiring (see Sources). If necessary, replace the kit’s threaded lamp pipe with one that’s long enough to run all the way through the lamp, so you can securely connect all the parts. Measure and cut this pipe to length so that everything screws together firmly (Photo 9). Make sure the bottom end of the rod has no sharp edges to cut the wiring I recommend installing a specialty grommet that screws over or slips inside the end of the rod to protect the wire.

Photo 9. Insert the cord in the lamp pipe and push through a sufficient length to make connections at the top end. A cord protector keeps the cord from rubbing against the rod.

Carefully follow the wiring instructions that come with the kit. Then, before you plug in the lamp, use a continuity tester (available at hardware stores) to verify that you’ve wired it correctly. The lamp is good to go if the tester’s light comes on when you touch one lead to the inside of the metal socket that the bulb screws into and the other lead to the wide tine on the cord’s polarized plug. If there’s no light, switch the wires on the socket’s terminals and retest. The tester’s light must come on for the lamp to be correctly wired.

Take the lamp with you to find a shade. The shade shown here is 12″ tall x 16″ dia. and sits on a 9″ harp. Don’t worry about tossing the harp that came with your kit in favor of one that fits the shade you’ve chosen. After all, the look of the lamp and shade together are far more critical than the size of the harp.

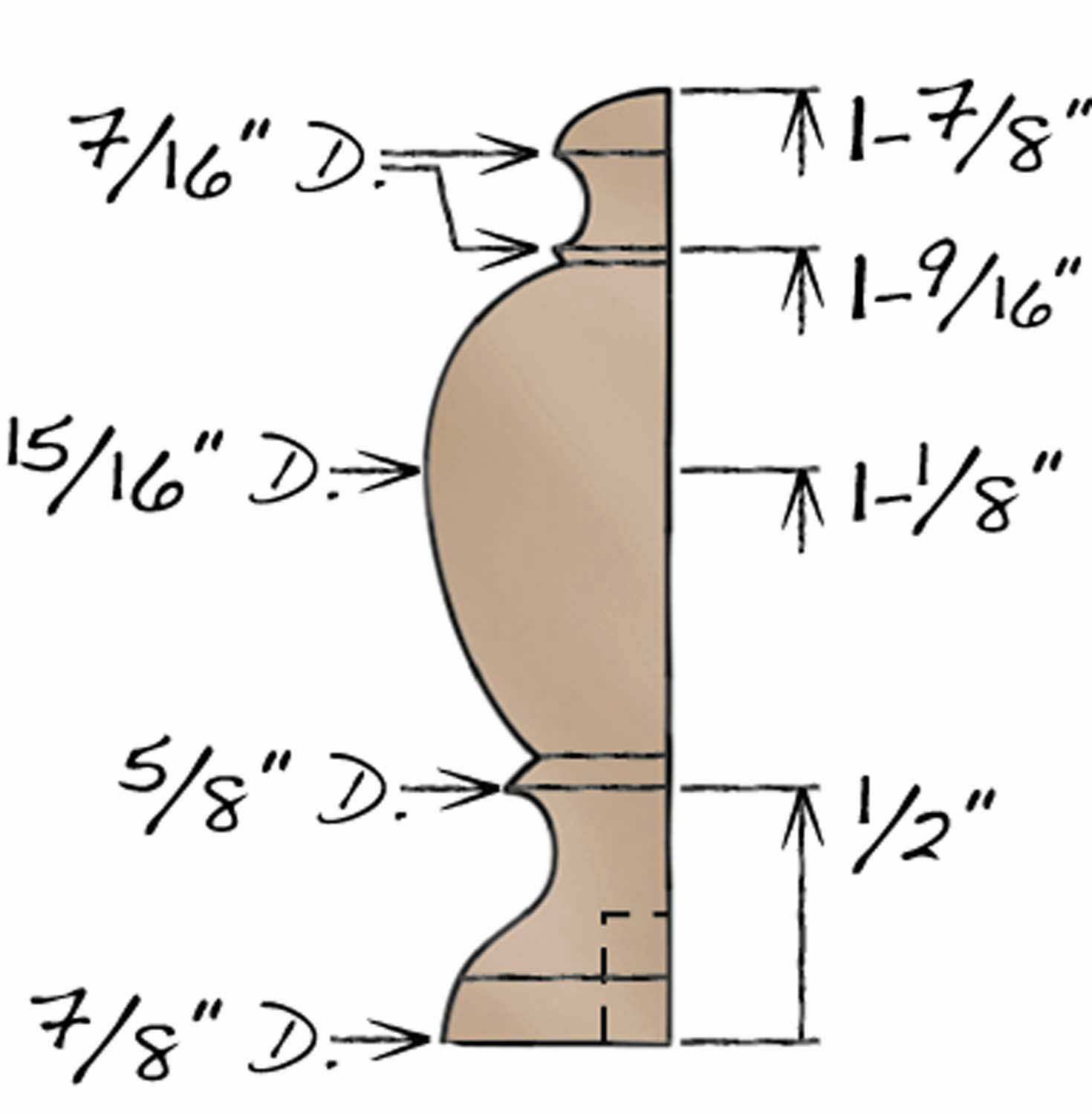

Similarly, turning your own finial is the perfect finishing touch, even though most kits come with one. I epoxied a nut sized to fit the harp (1/4″ x 28tpi) into a piece of ash, mounted it in a scroll chuck, turned it to echo the lamp’s form and applied the same finish.

Fig. A. Lamp Body Profile

Fig. B. Lamp Base Profile

Fig. C. Final Profile

Sidebar: Drilling on the Lathe

Shell auger bit

Use a shell auger bit to drill a center hole through a solid lamp body after it has been turned. This long bit (28″ in this case) pushes through a hollow tailstock and hollow lathe center, so your lathe must be so equipped (see Sources, below). Run the lathe at a slow speed, clear the chips often to keep the bit from binding and overheating, and stop just short of drilling through other end. When finished and off the lathe, enlarge the hole to 7/16″ using a bell hanger bit.

Bio

Alan Lacer is a turner, writer, demonstrator and instructor living near River Falls, WI. For more information, visit alanlacer.com.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.