We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

By Christopher Schwarz

From the Spring 2004 issue of Woodworking Magazine, pages 8-11

When I was taught to cut rabbets in my first woodworking class, we made them with two cuts on the table saw. You’ve probably seen this technique in books and magazines before. For the first cut, the work is flat on the table. For the second cut, you stand the work on edge and press it against the fence as you move the work over the blade. The waste falls away and your joint is complete.

I’ve always struggled with this technique. It never seemed to produce a perfect rabbet every time. The technique does have its strengths: Most woodworkers have a table saw and a rip blade to make the cut; when it works, it does produce a nice smooth joint. But after years of doing it this way, I concluded that this technique has several serious weaknesses:

- Standing the work on edge requires a tall rip fence, perfect balance on your part and a zero-clearance insert in your saw’s throat plate.

- The joint is time-consuming because it almost always requires two saw setups and several test pieces to get it just right.

- You have to move the saw’s guard out of the way for the second cut, no matter which brand of guard you have on your saw.

So we decided to look for a better way to make rabbets. We found two good methods. The first uses two scraps and a dado stack. The second is an improved two-step process that’s virtually foolproof. But before we get to that, a quick explanation on why other methods aren’t as great.

Rabbets by Hand Take Great Skill

Rabbets are one of the first joints woodworkers learn. Try building any sort of cabinet or shelf without it and you’ll know immediately how essential this simple open trench is.

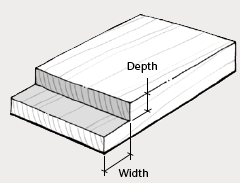

The perfect rabbet should have square shoulders and a flat bottom. And the cut should be smooth. You shouldn’t see marks from the tooling on the joint except on close inspection. If any of these elements of the joint are off, you can be in trouble at assembly time.

If the joint’s shoulders aren’t square, you likely are going to have an ugly gap between the rabbeted piece and its mate. Or worse, you will close the joint but the case will not be square. If the cut is rough, has burn marks or is inconsistent, it will be difficult to completely close the joint with clamps. Plus, a rough rabbet isn’t going to be as good a glue joint as a smooth one.

Before power tools, woodworkers made rabbets with hand tools, such as a rabbeting plane. I’ve done it this way, and it works great – once you master a couple of skills. Before you can cut this joint with a rabbeting plane, you need to learn to tune the tool and sharpen the iron. This is no small feat for a beginning woodworker. Then, once you have a tool that works, there are two settings that are paramount: the depth stop, which limits how deep the rabbet is, and the fence on the side, which controls the joint’s width. With these two set, you then make passes until the tool stops cutting – then your joint is complete.

I consider this a technique that’s best for the hand-tool enthusiast; it does take some skill. Most woodworkers are going to opt for an electron-eating solution with an easier learning curve, such as with the router or table saw.

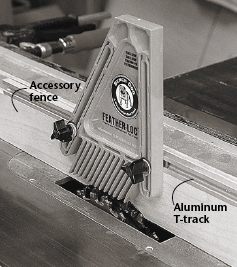

An accessory fence on your table saw’s rip fence allows you to make perfect rabbets with one machine setup and almost always in one pass.

Routers Aren’t for Everything

The router table was my first choice for a couple of reasons: Router cuts are exceptionally clean and maintaining the squareness of the joint’s shoulders is no problem.

But after cutting a lot of rabbets on my router table, I concluded that routers are not the best choice for all-around casework rabbeting. It sounds like blasphemy, but here’s what I concluded: Most routers actually are quite underpowered for the job, so you end up cutting your projects’ joints in small, time-consuming nibbles.

A 11⁄2-horsepower router does not deliver the same sustainable torque that a 11⁄2-hp contractor saw does (no matter what the tool’s label or packaging says). Part of the problem is marketing hype among the router manufacturers, and part of the problem is in the way a universal router motor is built compared to a traditional induction motor on a contractor saw. The bottom line is this: Ask a typical router to hog out a 3⁄4″-wide x 3⁄8″-deep rabbet in one pass and it will bog down or even stall in the cut.

A router also is noisier than a table saw, and large cabinet pieces become unwieldy when you try to maneuver them on the router table. You could cut smaller rabbets on small pieces on the router table (drawers are about the right scale for most router tables). But here’s how I feel about that: Learn the rabbeting process on one machine and then do it over and over the same way so you become an expert at that process. Jumping around from technique to technique will only slow your progress as you learn the subtleties of each.

Some people use their jointer and its rabbeting ledge to cut this joint. The jointer is a powerful machine, and this technique actually works pretty well for narrow stock such as face frames and door parts. But try to rabbet the end of a 30″ x 20″ cabinet side and you’ll see why this isn’t the way most people prefer to cut rabbets.

So I went back to the table saw, which has guts galore and a big table, to see if I could find a different way to skin this wily animal.

Single Setup with Stack Dado Set

One nice thing about making a rabbet on the router table is that you can (within reason) do it with a single tool setup. You can control the width and depth of the joint simultaneously, tweaking the height of the bit and the fence (which exposes the tooling) until the joint is just right.

To do this same thing on the table saw you need two things: a stack dado set and a long length of plywood you can clamp over the working surface of your rip fence. The wood allows you to “bury” the dado stack in the fence so it will work like the fence on a router table.

This accessory fence should be straight, at least 1⁄2″ thick and as long as the table saw’s rip fence. Plywood is a logical choice of material because it doesn’t tend to warp.

The first time you use this accessory fence, lower the dado stack below the surface of your saw’s table. Next, clamp the accessory fence to your rip fence and then position it so that about 1⁄8″ of it covers the blades below. Then, turn on the saw and slowly raise the blades into the fence until you’ve cut away about 1⁄4″.

Another necessity to ensure an accurate and safe cut is to use a featherboard that presses the work against the table. There are lots of commercial featherboards available, or you can certainly make your own. As you can see from the photo at right, I also added an aluminum T-track (in a rabbet, no less) that allows me to quickly adjust the featherboard’s position. That’s mighty handy when dealing with project parts that are of different thicknesses.

The same rules for ripping and crosscutting apply to rabbeting. For ripping cuts with the grain, use the fence to guide your cut.

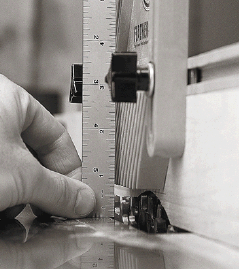

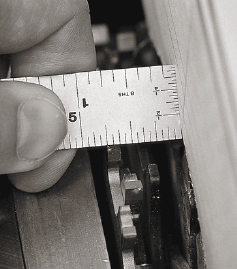

Now you’re ready to make rabbets. Using a 6″ rule (see “Almost-perfect 6″ Rulers” on page 25), set the height of the dado stack to equal the depth of the rabbet you want to cut. (Tip: Spend some time finding the point where your blade’s teeth are at their highest. When you’ve found that sweet spot, mark it on your table saw’s throat insert; I use a scratch awl. In the future, you can just set your ruler on that mark and measure. You’ll be amazed how much time this saves you.)

Next, set the saw’s rip fence to expose enough of the dado stack to make the width of your rabbet. With practice, you can almost always hit that measurement exactly on the first try. Lock the height of the arbor on your saw. This is especially important if you own a benchtop or contractor saw. In smaller saws, the mere force of the cut can cause the arbor to creep downward. If it creeps just a bit, that’s the worst. You might not find out about the problem until assembly.

Turn on the saw. Follow the same rules you do when ripping or crosscutting. If it’s a ripping operation, you can simply press the work against the fence and push it through the blades. The same goes for work that is square or nearly square (such as the side of a base cabinet). After your first pass, check the depth of cut with a rule or dial calipers all along the joint to make sure your featherboard is pressing down hard enough to prevent the work from rising during the cut. If the joint is inconsistent, increase the tension on your featherboard or push the work a little harder against the saw’s table.

Sometimes taking a second pass will fix your problem. While that’s not ideal, it’s worth a try if you are stuck and out of options.

Remember: Any cup or warp in your workpiece can ruin the accuracy. And plywood is not always as flat as we would like it to be. If you’re having trouble getting a consistent joint, check the work to see if it’s cupped or warped.

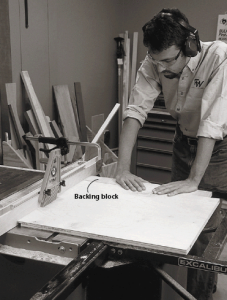

When crosscutting rabbets across the grain, you have two choices: Use a miter gauge if the stock is narrow or, for pieces wider than 8″, use the rip fence and a backing block behind the work. A backing block will stabilize the part during the cut. You don’t want to use a backing block to cut narrow pieces because the work could slide right into the cavity in the accessory fence. And that’s when you’ll find out how tough the anti-kickback fingers on your featherboard are.

For crosscutting across the grain, use the miter gauge for narrow pieces or use the rip fence and a backing block (to prevent tear-out) for larger pieces.

To rabbet the ends of large case sides you’ll definitely have to forego the miter gauge. Using a backing block here will reduce the chance that you’ll tear out the grain when your work exits the dado stack. As with ripping operations, making a second pass sometimes helps ensure your cuts are more consistent.

As a bonus, you can cut rabbets this way with an overarm guard in place. Because the guard obscures the blades, we’ve removed it for these photos, but it is an important part of the setup.

As much as I like this technique, it isn’t perfect. When crosscutting against the grain, the cut is a bit rougher than if you used a router, though I can’t report any gluing problems with the joints cut using a dado stack. Cuts with the grain, on the other hand, are quite smooth.

Another cause for concern is your saw’s motor. Benchtop saws don’t really have the guts to make casework rabbets (plus many don’t have a mechanism to lock the height of the arbor – a major problem). In fact, the fences of benchtop saws usually are too inaccurate to cut the joint using the two-step process mentioned earlier. If you own a benchtop saw, you should consider cutting your joints on a router table.

However, larger saws, such as contractor- and cabinet-style saws, usually breeze through these joints in one easy pass over the dado stack.

All things considered, I found that maneuvering workpieces on the larger table of the table saw is easier than cutting the same size pieces on the router table. Plus, the power of the table saw made the cuts easy to accomplish in one pass without taxing the machine or the tooling.

When making the cut in two stages, the first cut defines both the width and depth of your joint. Keep your work tight against the fence.

Fixing the Two-step Process

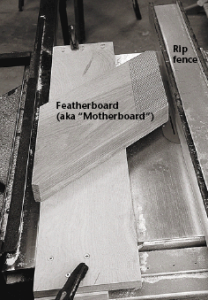

There also is a way to modify the two-step method on the table saw to make it work well for beginners or people uncomfortable with balancing pieces on edge. The trick is a featherboard. (The word “featherboard” doesn’t really do it justice. In our shop, we call it the “motherboard.”)

The “motherboard,” shown in the photos below, needs to press the work against the rip fence right over the blade, so it looks a little different than the one used with the dado stack. This “motherboard” is used only on the second pass.

The first pass defines the width and the depth of the rabbet. Use a saw blade with teeth that are flat on top, such as a ripping blade. A crosscut blade has teeth that score the work like a knife to cleanly remove the wood fibers; this will produce “V”-shaped channels in your work. Other blades, such as those with a triple-chip grind, will create even more problems, so stick with a rip blade.

To set the rip fence, measure from the outside or left edge of the teeth to the rip fence until you get the desired width of your rabbet. Lock the fence down. Then use your 6″ rule to set the blade height so it equals the depth of the rabbet. Again, marking the highest projection of your saw blade’s teeth on your saw’s throat plate will save you hundreds of test cuts per year.

Make a test cut with the work flat on the saw’s table, as shown in the photo below left. If you like, you can use a featherboard to hold the work flat on the table, similar to the way I did it with the dado stack setup shown on page 10.

This featherboard, which holds the work steady and against the fence, is the key to rabbeting on the table saw in two steps.

With your first cut complete, set up your saw to remove the rest of the waste from the rabbet. The critical dimension is the distance between the fence and the blade. In essence, this distance is the amount of wood you want to remain on your piece when the joint is complete. For example: You want to cut a rabbet that’s 1⁄4″ deep in a 3⁄4″-thick piece of wood. To make the second pass, you should set your fence so there’s exactly 1⁄2″ between the blade and the fence. When you set the blade’s height, adjust it until it trims away the waste but no higher. Your first cut already defined the corner of the rabbet.

It’s important that the waste falls to the outside of the blade. If the waste gets trapped between the blade and fence it will shoot back at you when it is cut. This can be less than ideal, depending on where you’re standing.

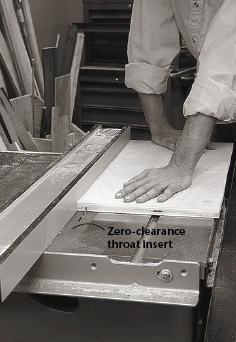

The other important point here is that you should either make or invest in a zero-clearance throat insert for your table saw. When you balance your parts on edge for this second pass, you want them to ride on as much table surface as possible. The stock throat insert that comes with most saws is too wide for this job.

Set up your featherboard so it presses the work against the fence but above the blade. It should allow the work to pass through the blade but keep it firmly against the fence. With the featherboard set, the cut is reasonably safe: The board will not tend to tip and the blade is buried safely in the work.

And the Winner is …

The “motherboard” keeps everything in place during the second pass. The result is a clean and accurate rabbet.

I’ve cut hundreds of rabbets using both of these setups and I generally prefer using the dado stack method because it has one saw setup and the cut is made in a single pass.

I also like being able to use our overarm guard during the cut, as well as work with the parts flat on the table at all times. But if you don’t have a dado stack (good ones start at about $90), the two-step method is a sound alternative.

We decided to find out which of these techniques some beginning woodworkers preferred – sometimes people who are new to the craft are more intimidated by a certain technique than veterans. After a day of cutting rabbets both ways, the two beginning woodworkers in our workshop were able to make amazingly accurate rabbets using both techniques.

The only notable difference was that the dado-stack method required a little more upper body strength to keep the work to the table – though the beginners were enamored with the simplicity of using just one pass. The two-step method required a bit more finesse, one more setup and a little math. I tend to avoid math when possible, so my preference was no real surprise. WM

Download all 16 issues of Woodworking Magazine.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.